7

3311857

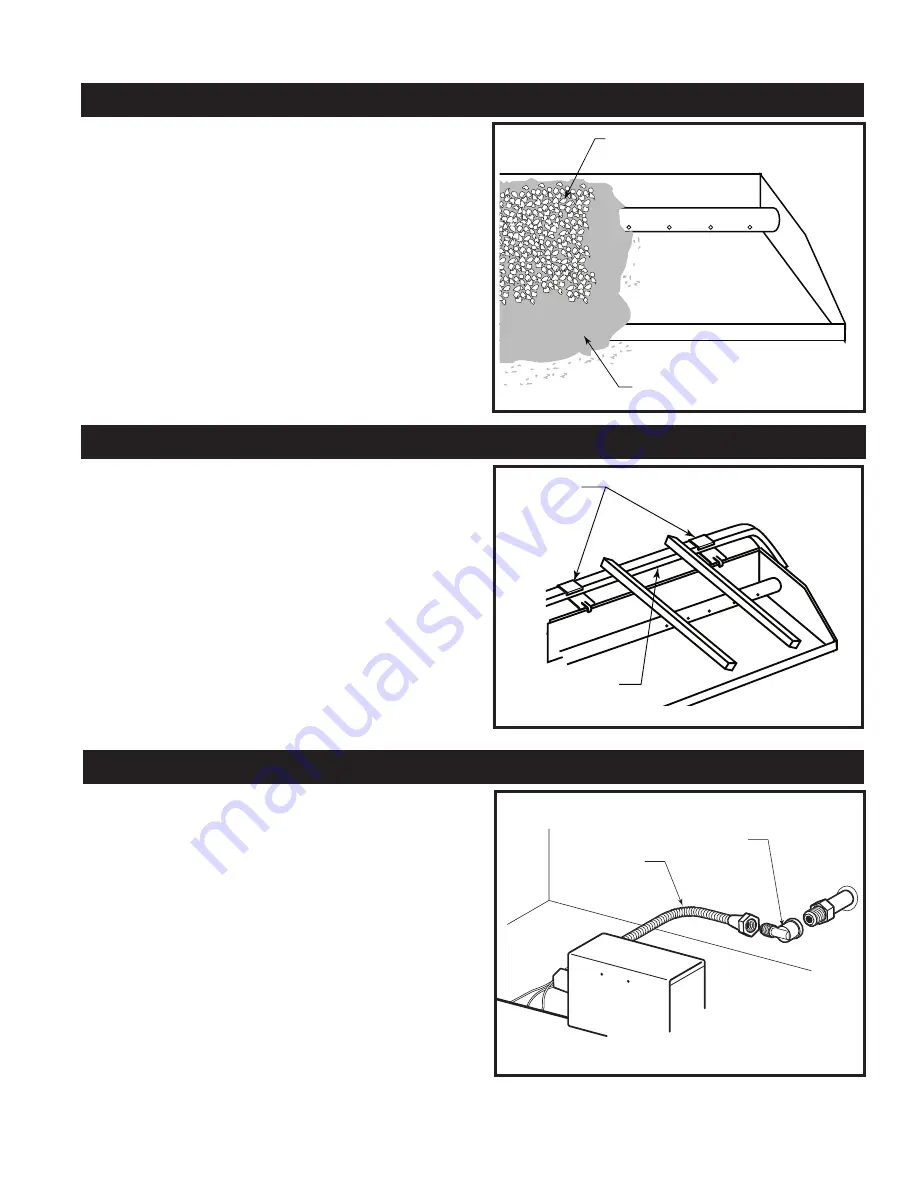

Adding Pan Material

1. Open the bag of Vermiculite and spread it

evenly across the Burner Pan, to the top, as

shown in Figure 5. You may overflow the front

and sides of the pan to cover the entire pan

and connecting hardware.

2. Next, open the bag of Glowing Embers and

place them on top of the Vermiculite, evenly

across the Burner Pan. Be sure to separate

the Glowing Embers into very small pieces

before placing them.

Connection To Gas Supply

1. Hook the U-Shaped part of the Grate Clips over

the back horizontal bar of the Grate, as shown

in Figure 6. Repeat with the other Clip.

2. Slide the rear edge of the burner pan into the

three-pronged slot in the front edge of the grate

clip, as shown in Figure 6.

1. Center the burner pan from left to right in the

fireplace and with the back of the grate against

the back wall of the fireplace.

2. Attach the Gas Supply Fitting onto your fire-

place’s gas supply pipe. Remember to use pipe

thread sealant or teflon tape on this connection.

3. Attach one end of the Flexible Gas

4. Connector to the brass fitting on the back of

the control valve, as shown in Figure 7.

5. Attach the other end of the Gas Connector to

the flared side of the Gas Supply Fitting.

Grate Clip Installation

LG216

ASHK

pan material

11/29/01 djt

Figure 5

Vermiculite

Glowing Embers

LG216

LG216

grate clip

11/29/01 djt

Figure 6

Grate Clip

Back Bar Of Grate

LG217

Flexible Gas

Connector

Figure 7

Gas Supply Fitting

LG218

Summary of Contents for SA18SHKRN

Page 18: ......