11

INSTALLATION, OPERATING, MAINTENANCE—JCV 360

JCV MOTOR s.r.o. , Vikýřovice 562, 788 13, Šumperk, Czech Republic—Europe, www.vernermotor.com, vernermotor@vernermotor.com

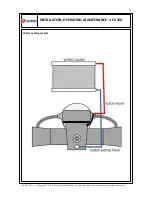

The system must to be perfectly deaerated after filling of the engine and radiator with

cooling liquid. See also illustration on page 22.

The correct procedure is:

1.

Squeeze the hose-pipes until the air bubbles flow into the radiator or expansion tank.

2.

Add the cooling liquid as needed.

3.

Tilt the engine to one side 30 degrees and again squeeze the hose-pipes till the air

bubbles flow out of the system.

4.

Put the engine back into the horizontal position and add cooland as needed.

5.

Repeat step 3. for 30 degrees tilt to opposite side.

6.

Put the engine back into the horizontal position and add cooland as needed.

7.

The system is deaerated after this step.

NOTE:

IF YOU DO NOT COMPLY WITH THE DESCRIBED PROCEDURE THEN AIR POCKETS MAY

FORM CAUSING THE ENGINE TO BECOME OVERHEATED, BE DEFORMED AND DAMAGED.

6. Oil system—

first fill up and working principle

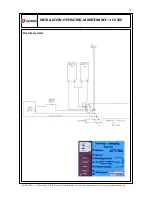

There are two outputs for connecting an oil cooler on the bottom of the engine.

Oil cooler is not an obligatory part of accessories. Oil cooler does not need to be used if the

oil temperature never exceeds maximum values. “Tubular organ“ type oil cooler, made of

8 mm diameter pipes. can be used instead classic oil cooler. Tubular organ type oil cooler

functions similar to classic oil cooler, but with less efficiency and smaller space demands. Oil

cooler should be placed as near to engine as possible and below the oil sump, otherwise

oil pump efficiency can be reduced.

Engine can be filled with new oil after oil cooler installation.

NOTE:

SEMI-SYNTHETIC OR FULL-SYNTHETIC TYPE JASO MA CLASS OIL FOR 4 STROKE MOTOR-

CYCLES CAN BE USED IN ENGINE ONLY.

Filling quantity is about 1 liter for engine and similar amount for oil pipes and oil cooler capa-

city. There is an oil level dipstick for checking oil level.

Remove spark plugs and crank engine by hand with ignition turned off after filling engine

with oil. This procedure may help remove air pocket in the oil system. Then crank engine by

electric starter – without propeller and still with ignition turned off. The oil pressure sensor

gauge should turn off within 10 seconds. Stop cranking engine and wait a moment if oil

pressure light doesn’t turn off by then a moment to allow starter motor to cool and crank

engine with electric starter again and watch oil pressure sensor gauge. Always watch electric

starter and never let it overheat. Stop cranking engine until electric starter gets cold again in

case the electric starter temperature is high. Engine oil system is still aerated if oil pressure

light doesn’t turn off.