193

A

PPLICATION

L

IQU

ID

R

ATE

C

ONTROL

CAUTION: Selection of the wrong data column or unit will result in misapplication of product.

Note: The only time the default rate is used by the system during product application is if the Rate Outside of

Field selection is set to " Rx default". This setting is located in the equipment configuration settings portion of

configuration setup. If the Rate Outside of Field selection is set to "Rx default", the default target rate will be

used when the vehicle exits the area covered in the prescription map.

L

IQUID

A

PPLICATION

D

IAGNOSTICS

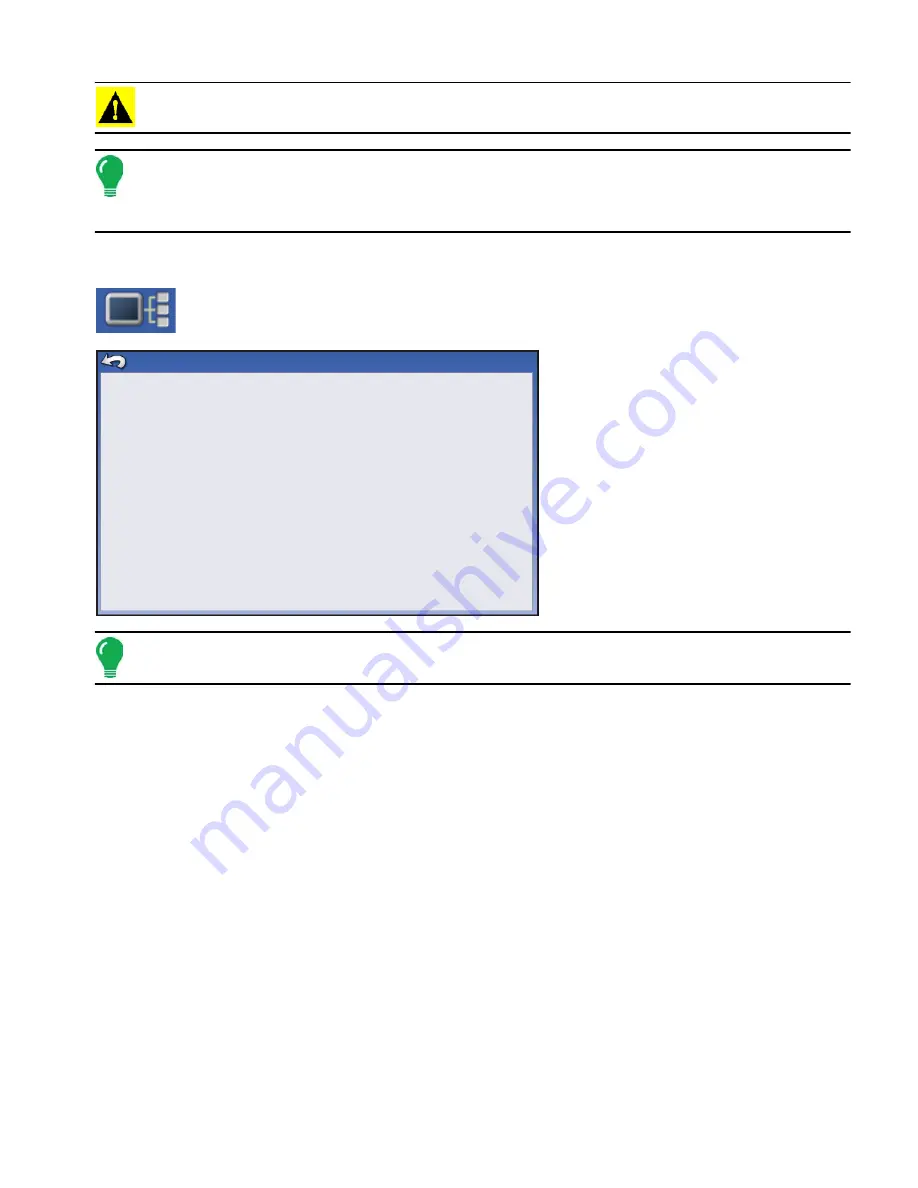

To go to the Liquid Diagnostics screen, press on the Device Information button. At the

Devices screen, highlight the item marked DC Liquid then press the Diagnostics button.

The Liquid Diagnostics screen includes

the Active Controller Name and the

Serial Number of the module. Other

information provided includes the Main

Pressure, Agitation Pressure, and

Auxiliary Pressure. These raw sensor

readings are shown in kilopascals (kPa).

Note: If you selected PWM as the Control Valve then the current PWM Duty Cycle is shown as a percentage

number, in the PWM Duty Cycle (%) item on the Liquid Diagnostic screen.

• Flow Meter Signal Frequency (Hz)

View the frequency generated by the flow meter during product application. Use this to make sure the flow

meter is providing continuous feedback.

• Flow Meter Pulse Count

provides a rolling count of pulses generated from the flow meter during product application. This diagnostic

item can be used to easily check that the flow meter is providing feedback to the system and also provides

a way to check flow meter cabling without changing settings within the system setup.

T

ROUBLESHOOTING

D

IRECT

C

OMMAND

L

IQUID

A

PPLICATIONS

Problem:

Boom indicators on the run screen of the display do not turn green.

Solution:

1. Make sure ground speed is registering a value greater than zero on the display.

2. Verify a target rate greater than zero is entered into the display.

3. Check the switch status found on the Run screen under System and Input Diagnostics. As the

boom switches are turned on and off, the Input Diagnostics window should change from black

to green (if they do not, then refer to the installation instructions to verify boom switch

connections).

4. Check high current connection into the Liquid Control Module.

Controller Name

Serial Number

Main Pressure (kPa)

Agitation Pressure (kPa)

Auxiliary Pressure (kPa)

PWM Duty Cycle (%)

Flow Meter Signal Frequency (Hz)

Fow Meter Pulse Count

DirectLiquid

2003750001

738

662

655

2.55

0

0

Liquid Diagnostics

Summary of Contents for ag leader

Page 1: ...Operators Manual Firmware Version 5 4 Ag Leader PN 4002722 Rev G ...

Page 2: ...Firmware Version 5 4 ...

Page 20: ...6 Firmware Version 5 4 ...

Page 38: ...24 Firmware Version 5 4 For more information see Legend Settings on page 52 ...

Page 55: ...41 SETUP M ANAGEMENT S ETUP Remove button Press to remove a business ...

Page 56: ...42 Firmware Version 5 4 ...

Page 78: ...64 Firmware Version 5 4 ...

Page 82: ...68 Firmware Version 5 4 Press to Export All Log files Export All Log Files ...

Page 84: ...70 Firmware Version 5 4 ...

Page 94: ...80 Firmware Version 5 4 ...

Page 108: ...94 Firmware Version 5 4 ...

Page 140: ...126 Firmware Version 5 4 ...

Page 154: ...140 Firmware Version 5 4 ...

Page 158: ...144 Firmware Version 5 4 ...

Page 162: ...148 Firmware Version 5 4 ...

Page 222: ...208 Firmware Version 5 4 ...

Page 244: ...230 Firmware Version 5 4 ...

Page 260: ...246 Firmware Version 5 4 ...

Page 290: ...276 Firmware Version 5 4 ...

Page 304: ...290 Firmware Version 5 4 ...