259

A

PPLICATION

S

TRIP

T

ILL

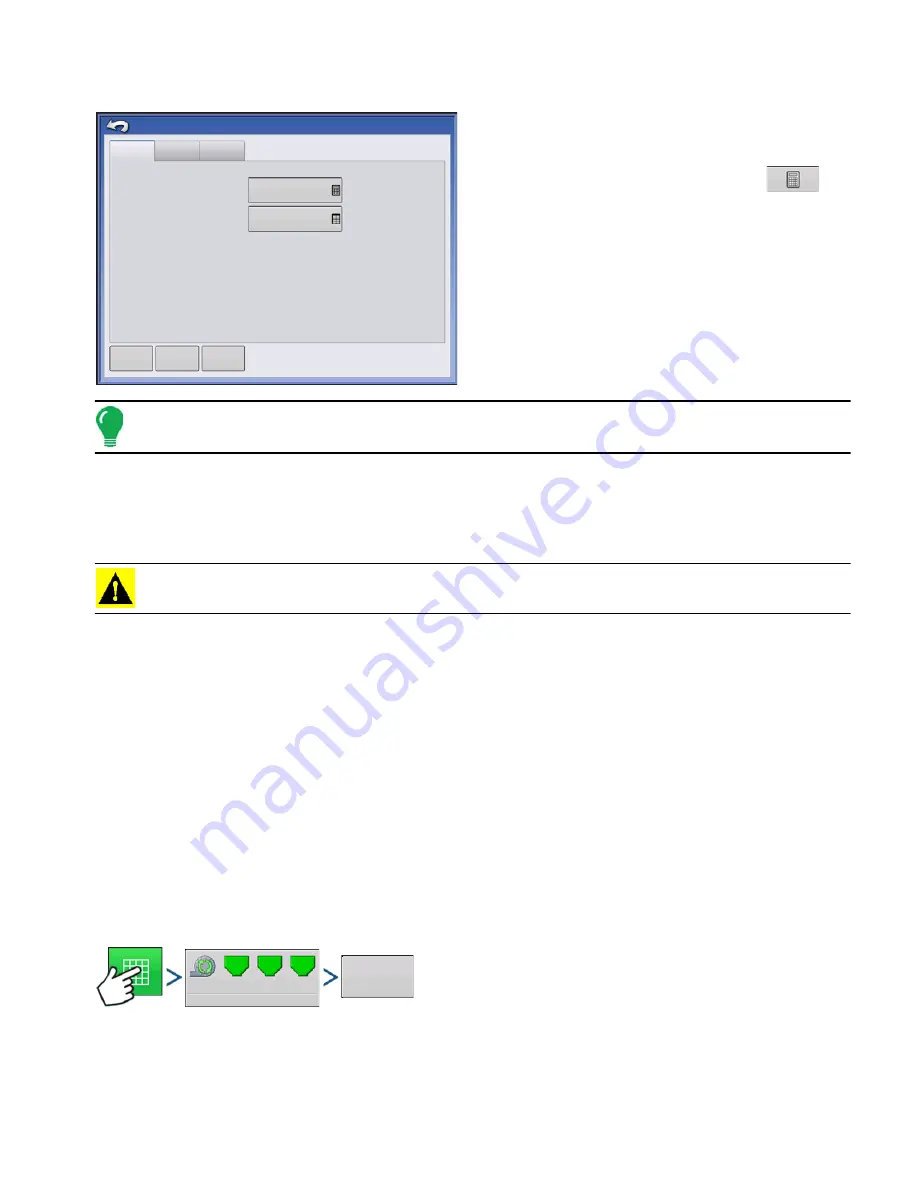

Strip Till Control Screen

• Product Density

This density value (shown in pounds per cubic foot, or

lb./ft.3), is stored with each product. Press

to

edit value.

Note: For proper machine performance and accuracy. Product Density should be measured for every

application load.

• Conveyor 1 Rate

This setting represents the volume of product dispensed by one revolution of the conveyor drive shaft (cubic

foot per revolution, or ft.3 /rev.) This number is shown with the assumption that the conveyor shaft has a 1-

inch gate opening.

CAUTION: You must either manually enter conveyor rate value or perform a CFR calibration routine for

each product and channel combination, otherwise misapplication will occur.

• Static Calibration

Press the

Static Calibration

button to perform an automated routine to calibrate each metering circuit. This

calibration is performed before applying in field conditions. For more information, see

Procedure for Hydraulic Drive systems” on page 259

• In-Field Calibration

Press the

In-Field Calibration

button to perform an automated routine to adjust the calibration number for

the selected metering circuit. This calibration is performed if there is a difference between the amount of

product logged as compared to what was actually applied. For more information, see

Procedure (Strip Till)” on page 261

.

Static CFR Calibration Procedure for Hydraulic Drive systems

You must perform a calibration for each granular product control channel (bin) for the equipment

configuration before applying in field conditions. This process is outlined below and on the following

page. The Static CFR Calibration Procedure performs an automated routine to calibrate each metering

circuit.

Press: Map button > Strip Till Control button > Static Calibration button

Channel 1

Channel 2

Channel 3

Prime

58 lb/ft

3

0.256 ft

3

/rev

DAP

Strip Till Control

Product

Density

Conveyor

Rate

Static

Calibration

In-Field

Calibration

3500

1

RPM

2

3

20

15

15

Static

Calibration

Summary of Contents for ag leader

Page 1: ...Operators Manual Firmware Version 5 4 Ag Leader PN 4002722 Rev G ...

Page 2: ...Firmware Version 5 4 ...

Page 20: ...6 Firmware Version 5 4 ...

Page 38: ...24 Firmware Version 5 4 For more information see Legend Settings on page 52 ...

Page 55: ...41 SETUP M ANAGEMENT S ETUP Remove button Press to remove a business ...

Page 56: ...42 Firmware Version 5 4 ...

Page 78: ...64 Firmware Version 5 4 ...

Page 82: ...68 Firmware Version 5 4 Press to Export All Log files Export All Log Files ...

Page 84: ...70 Firmware Version 5 4 ...

Page 94: ...80 Firmware Version 5 4 ...

Page 108: ...94 Firmware Version 5 4 ...

Page 140: ...126 Firmware Version 5 4 ...

Page 154: ...140 Firmware Version 5 4 ...

Page 158: ...144 Firmware Version 5 4 ...

Page 162: ...148 Firmware Version 5 4 ...

Page 222: ...208 Firmware Version 5 4 ...

Page 244: ...230 Firmware Version 5 4 ...

Page 260: ...246 Firmware Version 5 4 ...

Page 290: ...276 Firmware Version 5 4 ...

Page 304: ...290 Firmware Version 5 4 ...