4-2

TEL-29-N/NE

OPERA

TION

AERIAL LIFT OPERATIONS

This section emphasizes overall operating practices

for aerial lift operations. This information is presented

in the order of probable use while operating first from

the ground, then from the platform and close to

energized conductors.

Start Up Procedures When Operating From the

Ground:

Position the truck as described in this section.

In extremely cold weather allow the aerial lift to idle a

few minutes before engaging a load. Further

consideration of cold weather operation is addressed

in Service Procedures Section of Service Manual,

“Hydraulic Oil Recommendations”.

CAUTION

:

IF AN AERIAL DEVICE HAS

SET IDLE FOR AN EXTENDED LENGTH OF TIME

(I.E. OVERNIGHT) OPERATE IT FROM THE

LOWER CONTROLS THROUGH ITS FULL

RANGE OF MOTION SEVERAL TIMES BEFORE

AN OPERATOR ENTERS THE PLATFORM.

This procedure confirms that the lift is operating

properly and purges any air that may have become

entrapped in the hydraulic system. Select lower

control operation with the lower control selector

switch. Refer to the diagrams of lower controls in

this section. Always disengage the boom tie down

before initiating any lift movements.

If there is any kind of malfunction during this test

run, shut down the unit immediately. Do not operate

the lift again until the problem has been corrected by

the service department. Operate each lift function

from the lower controls by moving the spring-loaded

control switch in the desired direction, until motion

begins. To terminate a lift movement allow the spring-

loaded control switch to return to the centered or

neutral position. The standard rotation limit is

activated electrically. The boom raise, lower, extend

and retract movements, however, are mechanically

limited.

DANGER:

NEVER REVERSE OR

STOP THE DIRECTION OF LIFT TRAVEL

SUDDENLY AND AVOID REACHING THE END OF

BOOM RANGE AT EXCESSIVE SPEEDS.

STRUCTURAL DAMAGE OR INSTABILITY MAY

RESULT CAUSING DEATH OR SERIOUS INJURY.

mph (48 km/hr) or there is a threat of an electrical

storm.

2.

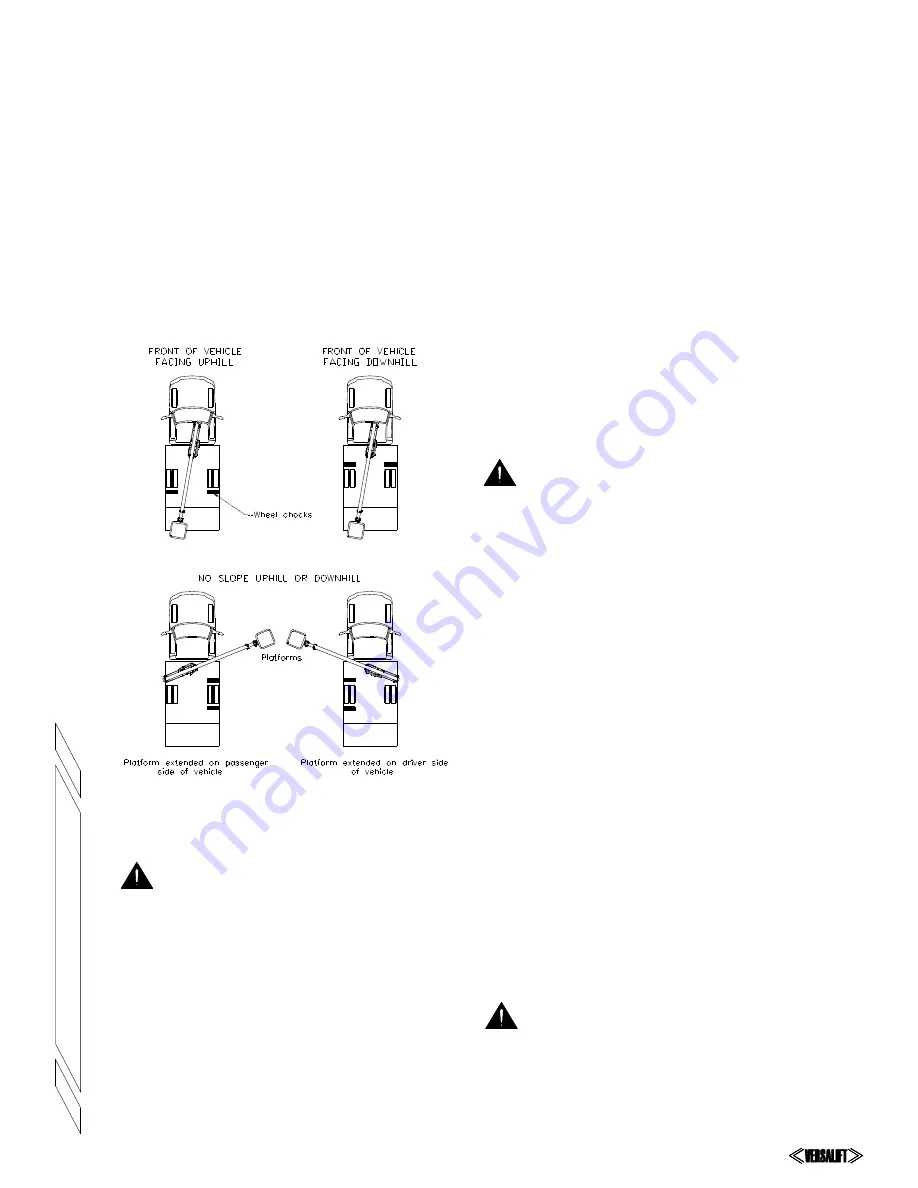

After leaving the cab chock the wheels. This is

extremely important because the brake

systems on some larger trucks have a critical

weakness. They may be engaged by locking

the drive shaft behind the transmission. If the

weight is reduced from one of the rear wheels,

by the position of the lift, the truck differential

can allow the truck to roll. Refer to the diagram

below for proper way of chocking the wheels.

Wheel Chocking Diagram

Figure 4.1

DANGER:

NEVER OPERATE THE

LIFT WITHOUT SETTING THE PARKING BRAKE

AND CHOCKING THE WHEELS. A ROLLING

TRUCK MAY CAUSE AN ACCIDENT RESULTING

IN DEATH OR SERIOUS INJURY.

3.

Set up adequate cones or barricades to mark

the boundaries of the work site and alert

pedestrians and motorists. Never work outside

the boundaries.

Summary of Contents for TEL-29-N

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ...1 2 TEL 29 N NE INTRODUCTION Figure 1 1 Model TEL 29 N NE Nomenclature ...

Page 11: ...2 3 TEL 29 N NE RESPONSIBILITIES SAFETY ...

Page 20: ...3 6 TEL 29 N NE SPECIFICATIONS ...

Page 22: ...3 8 TEL 29 N NE SPECIFICATIONS ...

Page 24: ...3 10 TEL 29 N NE SPECIFICATIONS ...

Page 25: ...3 11 TEL 29 N NE SPECIFICATIONS ...

Page 26: ......

Page 34: ......

Page 38: ......

Page 42: ...6 4 TEL 29 N NE DAILY VISUAL INSPECTION ...

Page 44: ...6 6 TEL 29 N NE DAILY VISUAL INSPECTION ...