6-1

TEL-29-N/NE

DAIL

Y

VISUAL

INSPECTION

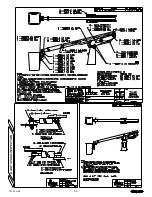

Torque-Seal Mark In Misalignment Condition

Figure 6.2

WELDS

- Refer to the “Critical Welds” drawing in this

section. All the welds should be inspected for signs

of fatigue. Rust and hairline cracks on a weld indicate

weld fatigue.

HYDRAULIC LINES

- Hydraulic lines should be

inspected for loose connections and frayed jackets.

Carefully examine the hoses, especially any portion

of hose subject to flexing and particularly the hoses

at the platform.

OIL LEAKS

- Oil leaking onto the truck floor or the

ground is sign of an impending problem. A hydraulic

leak will create a slippery surface which is potentially

hazardous. Hydraulic leaks must be repaired by

qualified service personnel and the unit must be

cleaned of excess hydraulic oil. If a hydraulic leak is

not repaired the oil in the reservoir will be depleted

and pump damage may occur.

ELECTRICAL SYSTEM

- Inspect electrical system

for damaged components. Check for bare electrical

wires and remove any trash or debris from around

elctrical components. Repair all damaged wires and

secure any loose electrical components or wires.

VEHICLE TIRES

- Check tires for the correct inflation

and for damage. Low pressure or damaged tires

are unsafe while driving the vehicle or operating the

lift.

LOOSE OBJECTS

- Inspect the booms for loose

objects (tools, spare parts, etc.) that might fall when

the booms are elevated.

HYDRAULIC OIL LEVEL

- The hydraulic fluid level

can be easily checked by monitoring the oil level

through the sight gages. The two sight gages are

mounted, one several inches above the other, on

the pedestal. The hydraulic oil level should be just

above the bottom of the top sight gage at full capacity

(7 gallons or 26.5 liters)

CONTROLS

- Operate all the lift controls through

the full range of motion to verify the controls are

functioning properly.

This aerial lift is designed to provide years of reliable

service with minimum maintenance. A routine

preventive maintenance program will assure

extended aerial lift service. The operator is responsible

for detecting maintenance problems during the daily

visual inspection, reporting the need for adjustments

or repairs, verifying that maintenance is performed

at the suggested intervals, and determining if the

aerial lift is in a good, safe operating condition. The

importance of accurate maintenance records cannot

be over emphasized. In order to judge the condition

of the aerial lift, the operator needs to be familiar

with the maintenance records of the aerial lift. Refer

to the “Maintenance Checklist” in Service Procedures

Section of Service Manual for the suggested interval

inspection information. The actual repair or adjustment

must be done by a qualified aerial lift mechanic.

Every day the equipment must be given a thorough

visual inspection to detect problems before they

become serious. During this inspection the operator

shall look for anything out of the ordinary that might

indicate a problem. Particular attention must be paid

to the following items. The Daily Visual Inspection

Checklist included in this section must be followed.

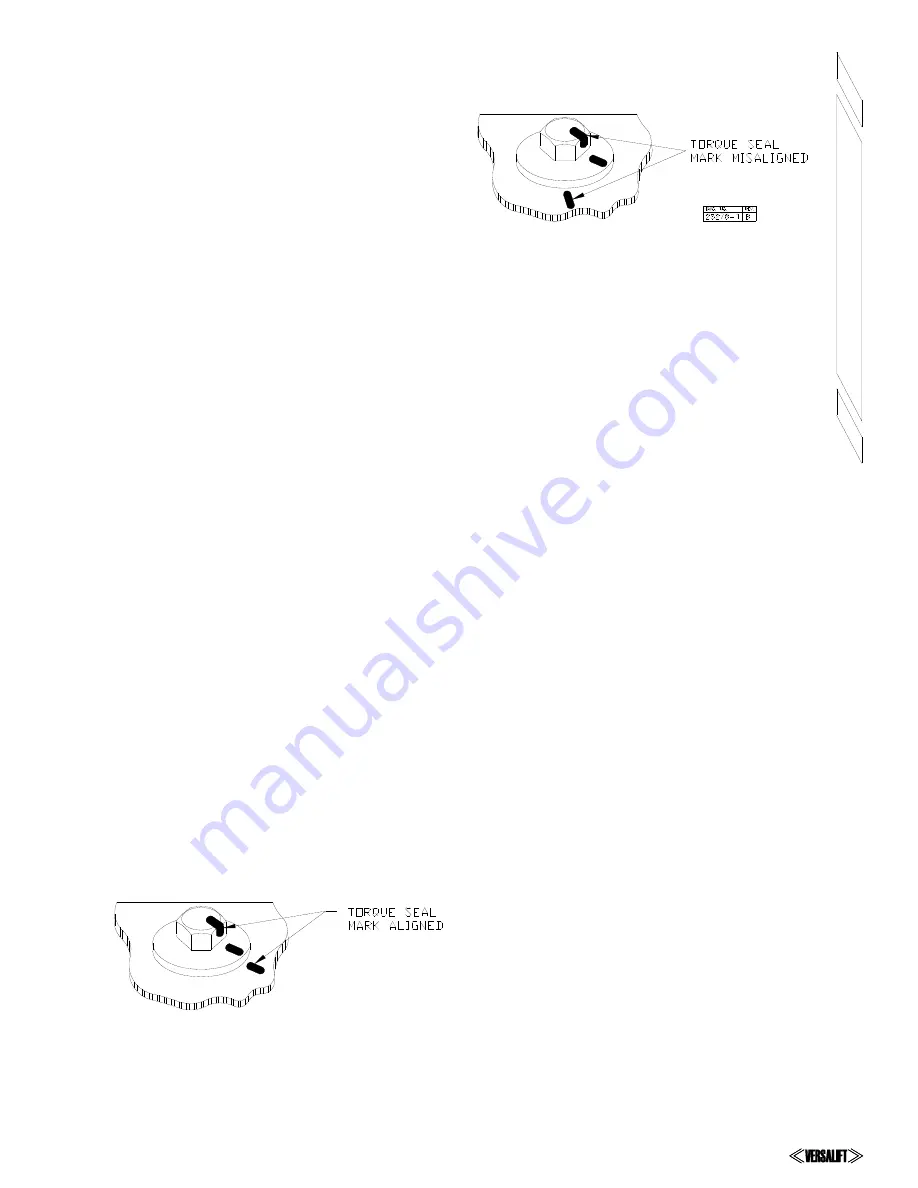

BOLTS

- Critical fasteners are identified on the

“Critical Fasteners” drawing in this section. All major

sections of the

Versalift

are bolted together and it is

vital that these bolts remain tight. Visually inspect all

the bolts for signs of relative movement. Pay

particular attention to the load supporting bolts

(rotation bearing bolts, pedestal/subframe mounting

bolts, platform rotator bolts). Critical bolts are Torque-

Seal marked to provide a quick means of detecting

any turning. Do not use the lift if the Torque-Seal

mark between the bolt head and mounting surface,

are not in alignment. Refer to Maintenance and

Inspection Schedule in Service Procedure Section of

the Service Manual for recommended torque

procedures and torque chart specifications. Refer to

Figure 6.1 and 6.2 for Torque-Seal mark conditions.

Torque-Seal Mark In Acceptable Condition

Figure 6.1

DAILY VISUAL INSPECTION

Summary of Contents for TEL-29-N

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ...1 2 TEL 29 N NE INTRODUCTION Figure 1 1 Model TEL 29 N NE Nomenclature ...

Page 11: ...2 3 TEL 29 N NE RESPONSIBILITIES SAFETY ...

Page 20: ...3 6 TEL 29 N NE SPECIFICATIONS ...

Page 22: ...3 8 TEL 29 N NE SPECIFICATIONS ...

Page 24: ...3 10 TEL 29 N NE SPECIFICATIONS ...

Page 25: ...3 11 TEL 29 N NE SPECIFICATIONS ...

Page 26: ......

Page 34: ......

Page 38: ......

Page 42: ...6 4 TEL 29 N NE DAILY VISUAL INSPECTION ...

Page 44: ...6 6 TEL 29 N NE DAILY VISUAL INSPECTION ...