VERTEX VD 26 SERIES

USER MANUAL

The Vertex VD series Temperature Controllers are a “Low Cost” Digital alternative to analog

controllers

, designed for use in simple applications where three term (PID) control is not required.

It

comes from the factory with default settings making it an “on/off” controller but can be user configured to have

proportional action “proportional”. It has a single digital display allowing access to all the parameters including

the “Process Variable” and “Set Point”. It is fully configurable on input including PT100 (RTD).

There are three simple steps required to get you up and running:

1.

Installation 2. Wiring 3. Commissioning

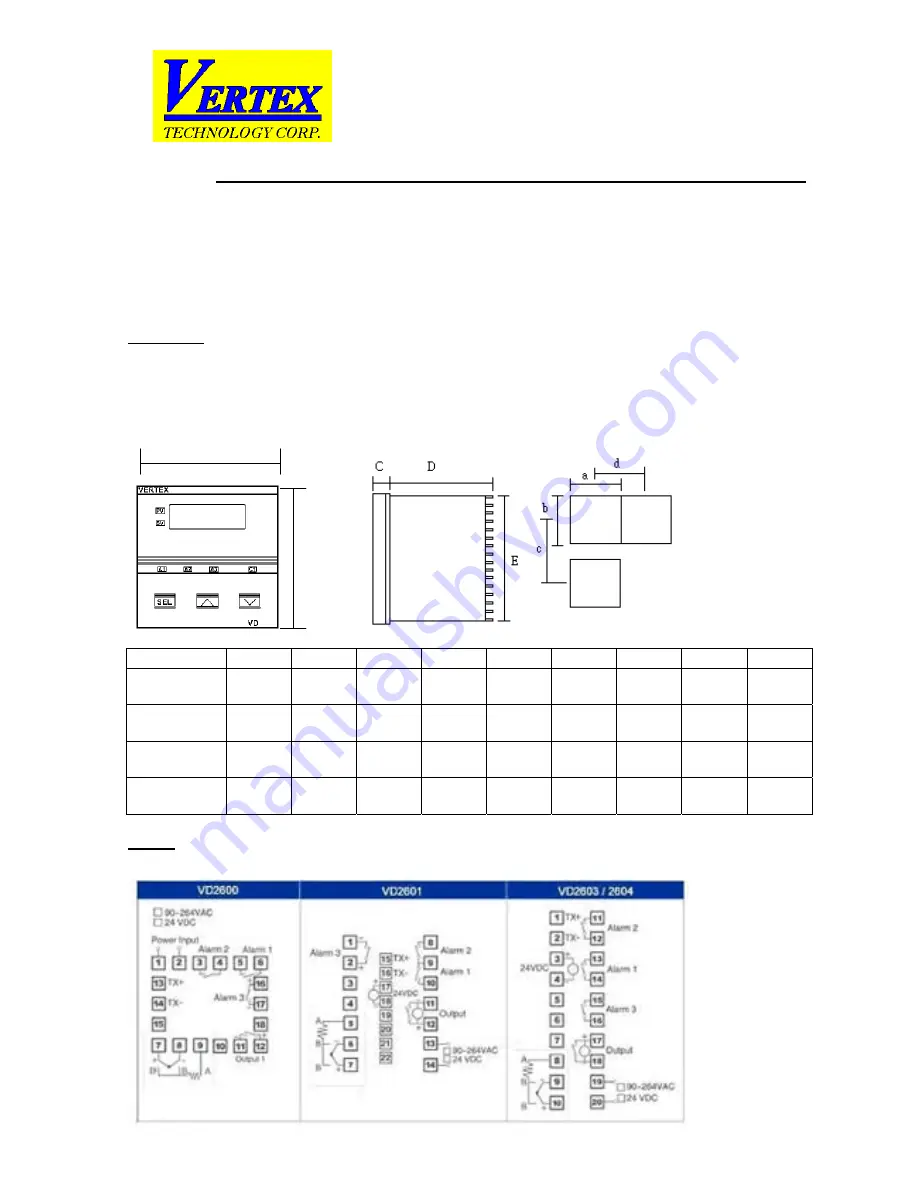

Installation

Select the panel cut-out sizes from the table depending on the Model VD controller you have chosen and install

the controller accordingly in your panel.

■

PANEL CUTOUT

:

B

A

Model A B C D E a b c d

VD-2600

48 48 6 100 45

45

+0.5

45

+0.5

60 48

VD-2601 72 72 9 80 67

68

+0.5

68

+0.5

90 72

VD-2603 96 48 9 80 45

92

+0.5

45

+0.5

48 120

VD-2604 96 96 10 80 91

92

+0.5

92

+0.5

120 96

Wiring

■

WIRING DIAGRAM

:

1