Page 19

VP-X Installation and Operating Manual

Rev. D (August 5, 2020)

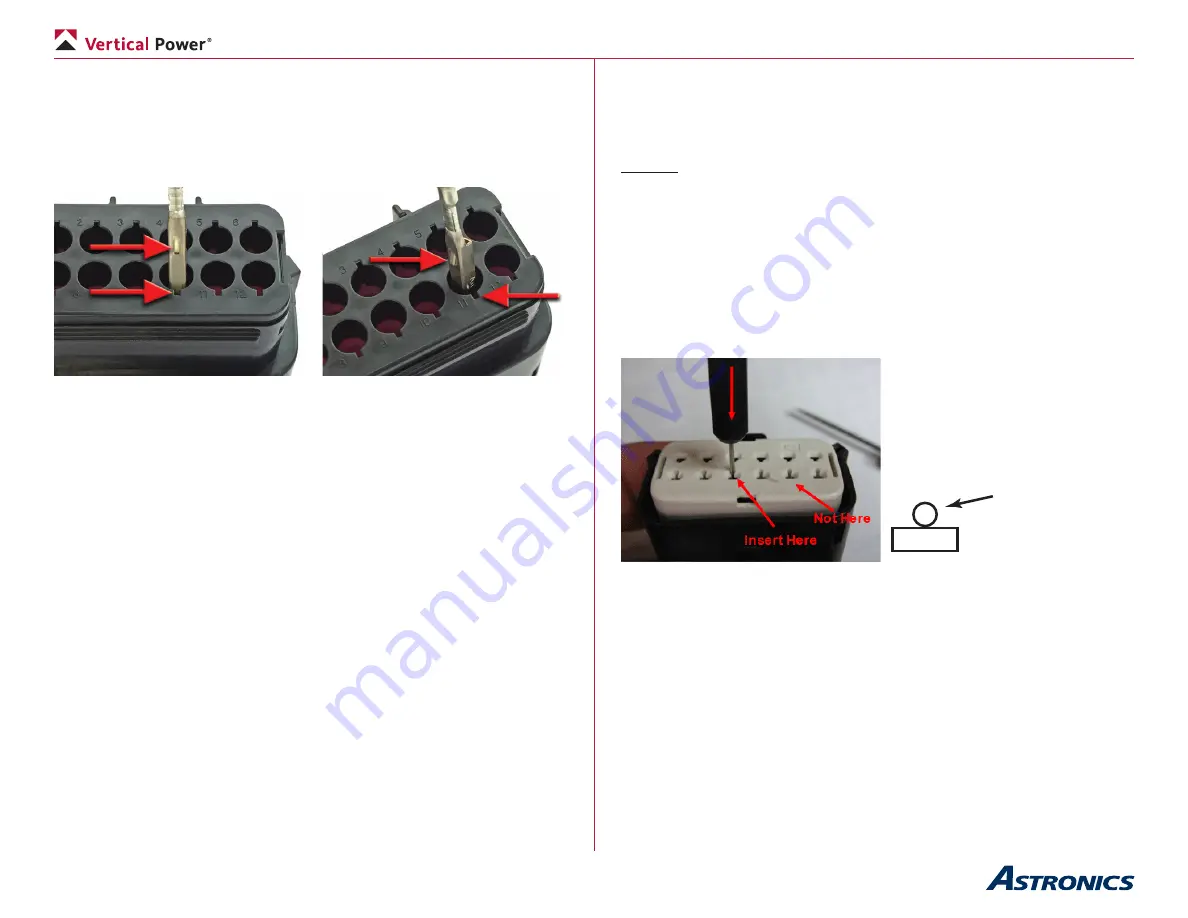

Step 3

: With the white insert still in the ‘out’ position, align the terminal to

rear of connector. Align the orientation feature as shown and insert through

appropriate opening. If resistance is encountered, retract the terminal and

adjust the angle of insertion. Continue inserting the terminal until it stops with

an audible click. Give the wire a slight tug to make sure it is seated properly.

It should not come back out.

Orientation feature on terminal

90° mis-orientation

aligned with index on housing

Not a straight entry

Troubleshooting:

The terminal should insert smoothly into the connector housing. If it does not,

the following are the most likely causes:

• The terminal is rotating while you are inserting it. The terminal must

remain aligned until it is fully inserted.

• The tangs on the insulation crimp may not be fully closed. Gently

squeeze the tangs closed around the insulation with a pair of pliers.

• The white insert may have closed. Open the insert.

Step 4

: With the terminals fully installed, the white insert can be seated into

its final lock position by applying an even force to both ends until it comes to

a stop, with an audible click. The white insert should move a distance of 5.0

mm (about ¼”).

4.7b Removing terminals

Steps 1 & 2

: Follow these steps as shown above to raise the white part of

the connector.

Step 3

: Using the pin removal tool, insert the tip into the terminal service hole

adjacent to the terminal to be serviced.

Step 4

: Push down gently to release locking finger. You will hear a gently

click.

Do not apply any lateral force, as this may damage the connector

or the terminal!

Step 5

: With the white insert still in the ‘out’ position, gently pull on the wire to

release the terminal.

If the terminal resists, the service tool may not be fully engaged. Remove

the tool and re-try. Push the service tool further into the service opening to

ensure that it has fully disengaged the locking finger.

Insert Here

Do not insert the tool into the terminal opening!

Do not use excessive force, excessive force can damage the connector!

Step 6

: The white insert can be seated into its final lock position by applying

an even force to both ends until it comes to a stop, with an audible click. The

white insert should move a distance of 5.0 mm

(about ¼”).