Page 53

VP-X Installation and Operating Manual

Rev. D (August 5, 2020)

5.30

Retractable Gear Wiring

The VP-X provides a source of circuit protected power for the gear switch.

Wire the gear system per the airframe manufacturer’s instructions.

5.31

Testing Individual Circuits

At this point, all the power wires should be connected to their respective

devices. The purpose of this step is to verify correct installation of the wiring.

Taking your time and being methodical on this step will save

troubleshooting time later.

Make sure that the following bulleted items are carefully

checked prior to proceeding.

• Disconnect the large wire going to the starter to eliminate any chance

that the starter may be accidentally engaged. Temporarily cover the

exposed end of the wire with electrical tape.

• Make sure that the propeller area is clear and can rotate freely.

• Verify that the fuel system is sealed or empty.

•

Verify that the area around and under the flaps is clear.

• Verify that the area around the trim motors and tabs is clear.

• Verify the high-voltage strobe wiring is either sealed or connected to

a strobe light.

• Check for any other conditions that may be problematic during

testing.

When I measure a pin that is “off” with a digital multimeter, I

get a voltage reading. Is this normal?

Solid-state switches have a characteristic called stray or

phantom voltage that will read slightly below bus voltage on a

power pin even when that pin is off. Don’t worry, it won’t cause

sparks or arcing. There is no “power” behind the voltage, it

is simply an artifact of the solid-state switches (a specialized

transistor). In order to measure voltage correctly, there

needs to be a load on the pin, like a test lamp, when taking

measurements. If the pin is off, the voltage will be zero when

there is a load on it. If the pin is on it will read at bus voltage

when there is a load on it.

Then proceed with the following steps:

• Turn off the master switch.

• Disconnect the wiring harness connectors from J1, J2, J8, J10, J12

on the VP-X.

• Verify that the correct wire is in the correct connector location using

the Load Planning worksheet as a reference.

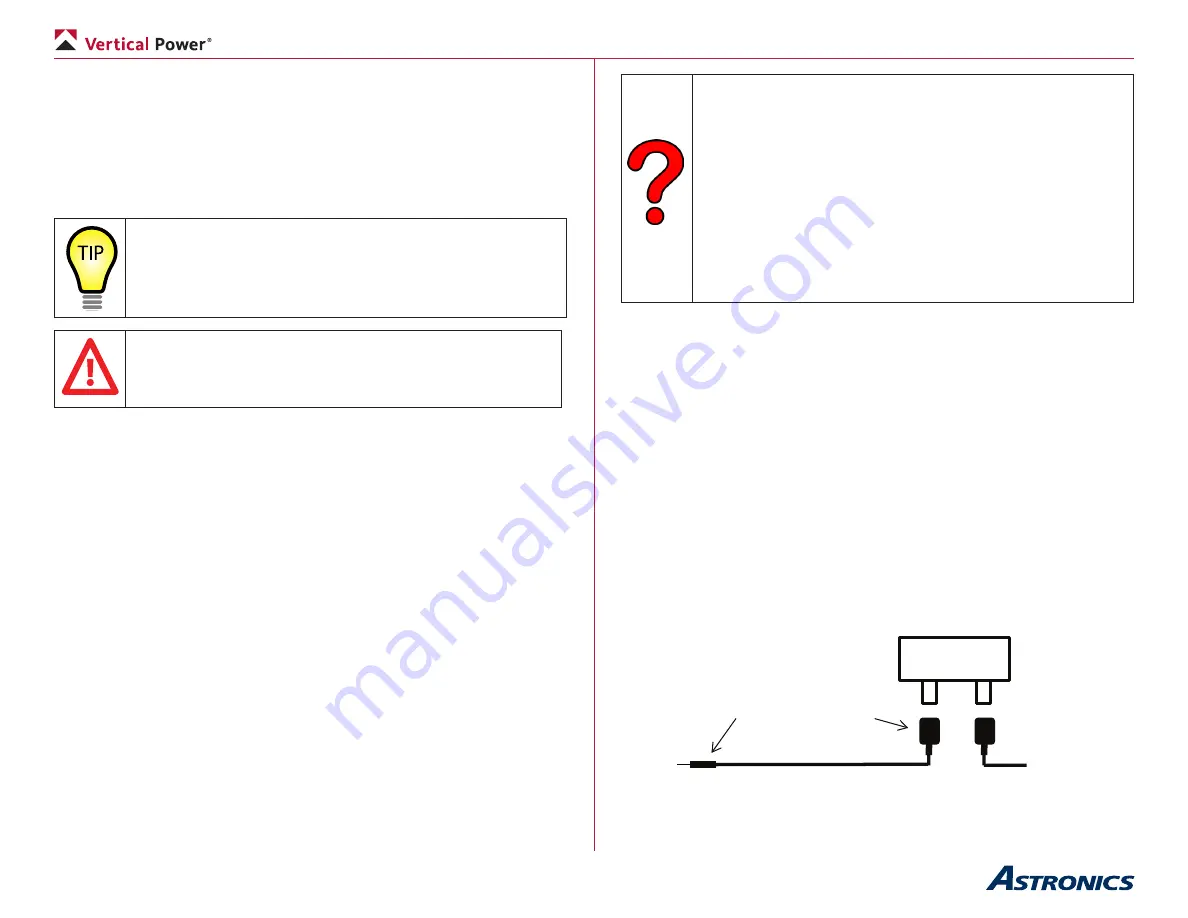

• Prepare test leads for the d-sub connector using two 20 or 22 gauge

wires about 10ft long each with a female d-sub connector terminal

crimped on one end and an in-line 2A fuse on the other.

• Prepare test leads for the power connectors using the test leads in

the wiring harness kit, attach spade terminals to an appropriately

rated blade fuse and then to the battery or hot wire. Using a bare-

end wire, paperclip or screwdriver rather than the male terminal on

the test lead may damage the gold coating on the terminals inside

the connectors.

Batt +

ATC FUSE

Spade

Terminals

Male

terminal

for power

connector