Vertiv™ XTE 802G Generator Room Walk-In-Cabinet Description and Installation Manual

24

6

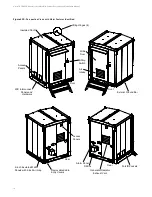

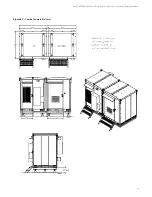

XTE 802G Placement

6.1

Overview

This section contains the procedures required for physical installation of the XTE 802G.

6.2

Site Selection

Obtain rights-of-way and other permits (building permit, electrical permit, etc.), depending on local codes and authorities, prior to

installing the XTE 802G.

The XTE 802G is to be installed using one of the following approved foundation kits and options:

1.

WIC Helical Foundation Kit - Helicals screw into the ground 6 feet removing the need for a ground ring. Two kits required,

one for the XTE 802 and one for the XTE 802G.

2.

Combo Helical Platform - Helicals screw into the ground 6 feet removing the need for a ground ring.

3.

Combo Concrete / On The Ground Platform - To be installed on grade or on concrete.

Site Location Considerations

Consider the following when deciding on the location for the XTE 802G.

•

Place the XTE 802G on servitudes, on dedicated (recorded) easements, or on property owned by the company. Avoid any

unrecorded easements.

•

Use public road and street rights of way only where there is enough space to place the XTE 802G and provide safe working

conditions. The XTE 802G should be easily accessible with adequate parking to ensure safety for people and vehicles. Place

the XTE 802G where it will not create a visual or physical obstruction to either vehicles or pedestrians.

•

Select locations that will minimize accidental or intentional vandalism. Consider the use of protective posts/bollards when

the XTE 802G is located near parking areas where vehicles could back into it.

•

Do not place the XTE 802G in ditches or areas subject to flooding.

•

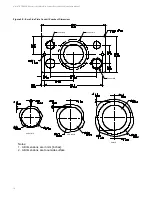

on page 8 shows the minimum working space allowed between the XTE 802G and any obstruction including

fences, hedges, etc. Working space consists of adequate area for craft personnel to perform work and maintenance

procedures as defined in the National Electric Code (NEC).

•

Where ordinances or other standards require that the XTE 802G be placed behind vegetation, preference should be given to

evergreens that will not produce leaves, sticky pollen or waste that could fall and clog the climate control units vents.

•

If the area is subject to freezing temperatures, be sure to comply with the local building codes and footing requirements to

eliminate the possibility of frost heave.

•

Minimize snow buildup around the XTE 802G and its externally mounted components.

•

Placement should support access for snow removal equipment in the event of a snow/ice storm.