User Manual 10H52258UM60 - Rev. 3 - 01/2019

82

APM 400/600

Optional Components

Yellow LED. On = The LBS adapter is connected to a non-APM UPS; Off = The LBS adapter is

connected to an APM UPS

SWITCH

The switch should be placed to right if the LBS adapter is connected to an APM UPS and to left if the

LBS adapter is connected to a non-APM UPS

Parameter

Specification

Voltage

120 Vac ~ 277 Vac

Frequency

45 Hz ~ 65 Hz

Current

1.5 A max.

Electrical Parameters

See Table 9.3 below for the LBS adapter electrical parameters

Installation

Note

Before discussing the installation process, remember that only qualified and trained personnel are allowed to install

the LBS adapter due to the hazardous voltage that may exist at the UPS output terminals.

Mounting the LBS adapter

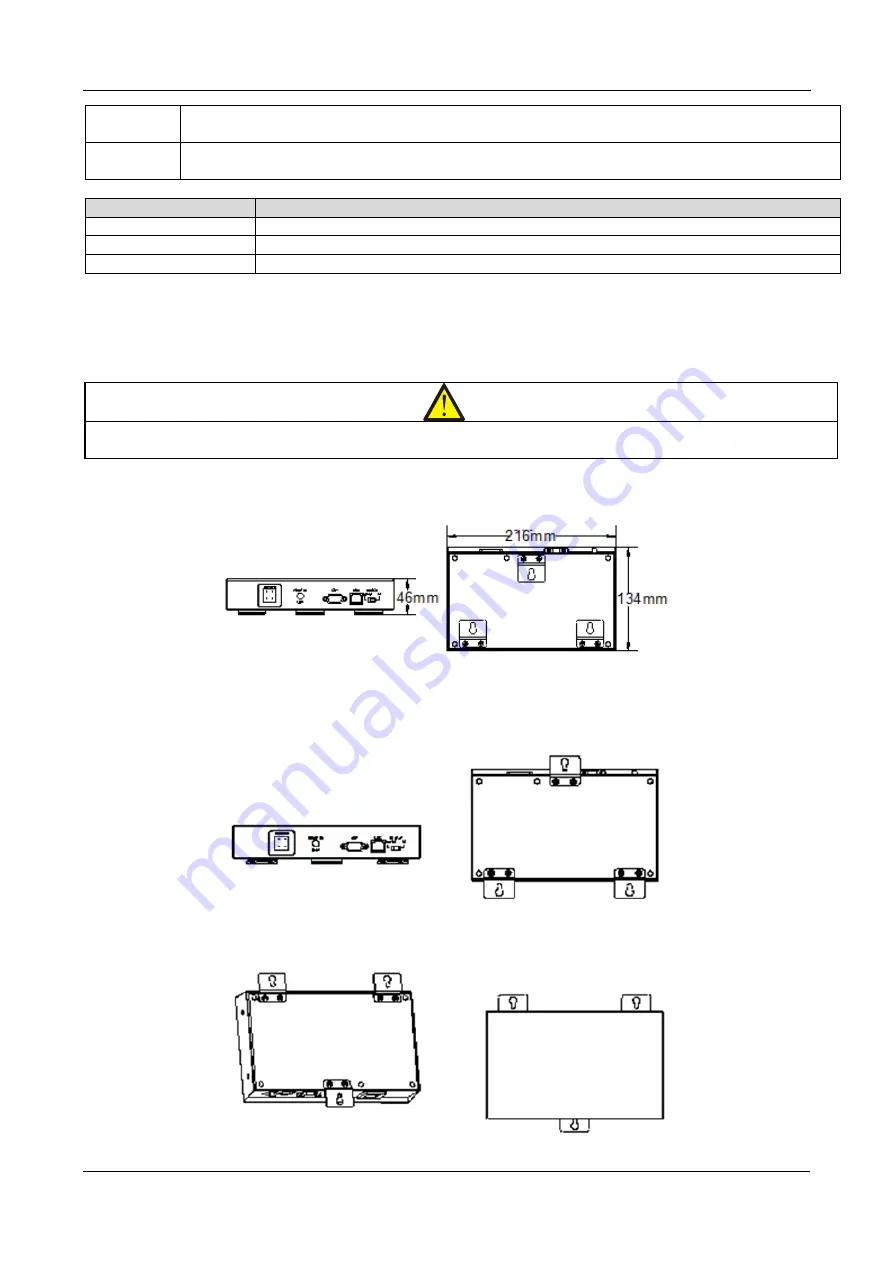

The dimensions of the LBS adapter are indicated in Figure 9-6.

Figure 9-6 LBS adapter dimensions

The LBS adapter may be installed horizontally or vertically, as indicated in Figure 9-7.

Horizontal installation

Vertical Installation

Figure 9-7 Horizontal and Vertical installation