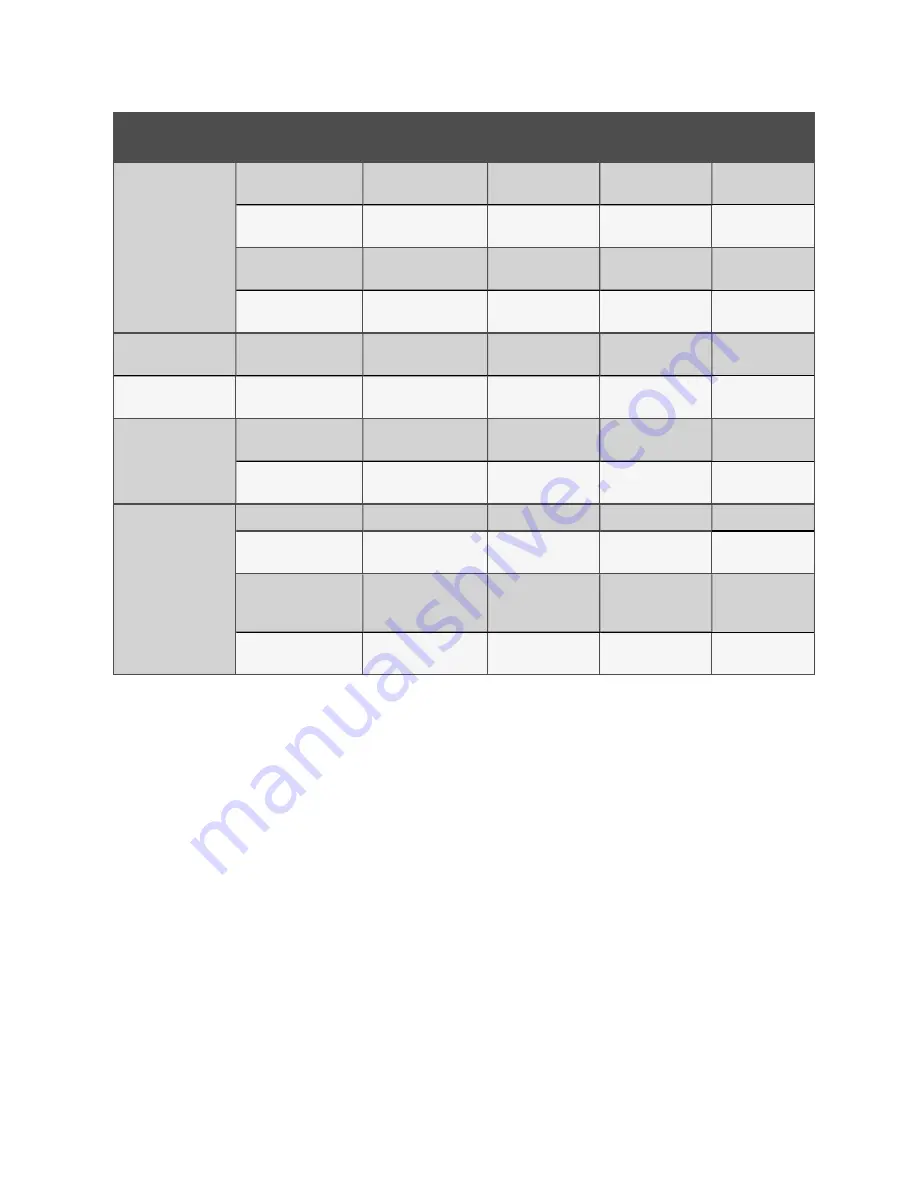

Component

Check Items

Maintenance Period

Monthly by user

3 months

6 months

1 year

Electronics

Check the condition of

contactors

X

Check electrical

connections

X

Check the operation of

controller

X

Check unit operation

sequence

X

Humidifier

Check steam hoses

conditions

X

Humidifier cylinder

Check humidifier cylinder

conditions

X

Electric heater

Check the operation of

the electric heater

X

Check the erosion of the

electric heater

X

Chilled water circuit

Check circuit for leakage

X

Check water (glycol) inlet

temperature

X

Check the operation of

the water regulating

valve

X

Check mixture glycol

level (if applicable)

X

9.2 Facility Fluid and Piping

Maintaining facility water and glycol quality is required throughout the life of the coolant fluid piping system. A coolant-fluid

maintenance program must be established that will evaluate fluid chemistry and apply necessary treatment. The

complexity of water/glycol solution condition problems and the variations of required treatment programs make it

extremely important to obtain the advice of a competent and experienced water-treatment specialist and follow a

regularly-scheduled coolant-fluid system-maintenance program.

9.3 Glycol Solution

It is difficult to establish a specific schedule of inhibitor maintenance because the rate of inhibitor depletion depends upon

local water conditions. Analysis of water samples at the time of installation and through a maintenance program should help

to establish a pattern of depletion. A visual inspection of the solution and filter residue is often helpful in judging whether

active corrosion is occurring.

9 Maintenance

58

Vertiv™ Liebert® CRV CRC30 and CRC60 Chilled Water Cooling System User Manual