9 Maintenance

WARNING! All maintenance operations must be carried out strictly observing the European and National

accident prevention regulations, especially the accident prevention regulations concerning electrical

systems, refrigerators and manufacturing resources. Maintenance may be done to air conditioning

equipment only by authorized and qualified technicians. To keep all warranties valid, the maintenance must

adhere to the manufacturer’s instructions.

WARNING! The work should be done on the system only when it is at switched-off. Stop the system by

switching off the air conditioner at the controller and the main switch. Check that the electrical components

of device are off and not receiving a power supply.

NOTICE

Only original spare parts made by Vertiv may be used. Using third-party material can invalidate the warranty.

When the spare parts must be brazed, be careful not to damage the internal parts (gaskets, seals, o-rings, etc.).

NOTICE

Risk of release of hazardous substances into the environment. Can cause environmental pollution and violation

of environmental regulations.

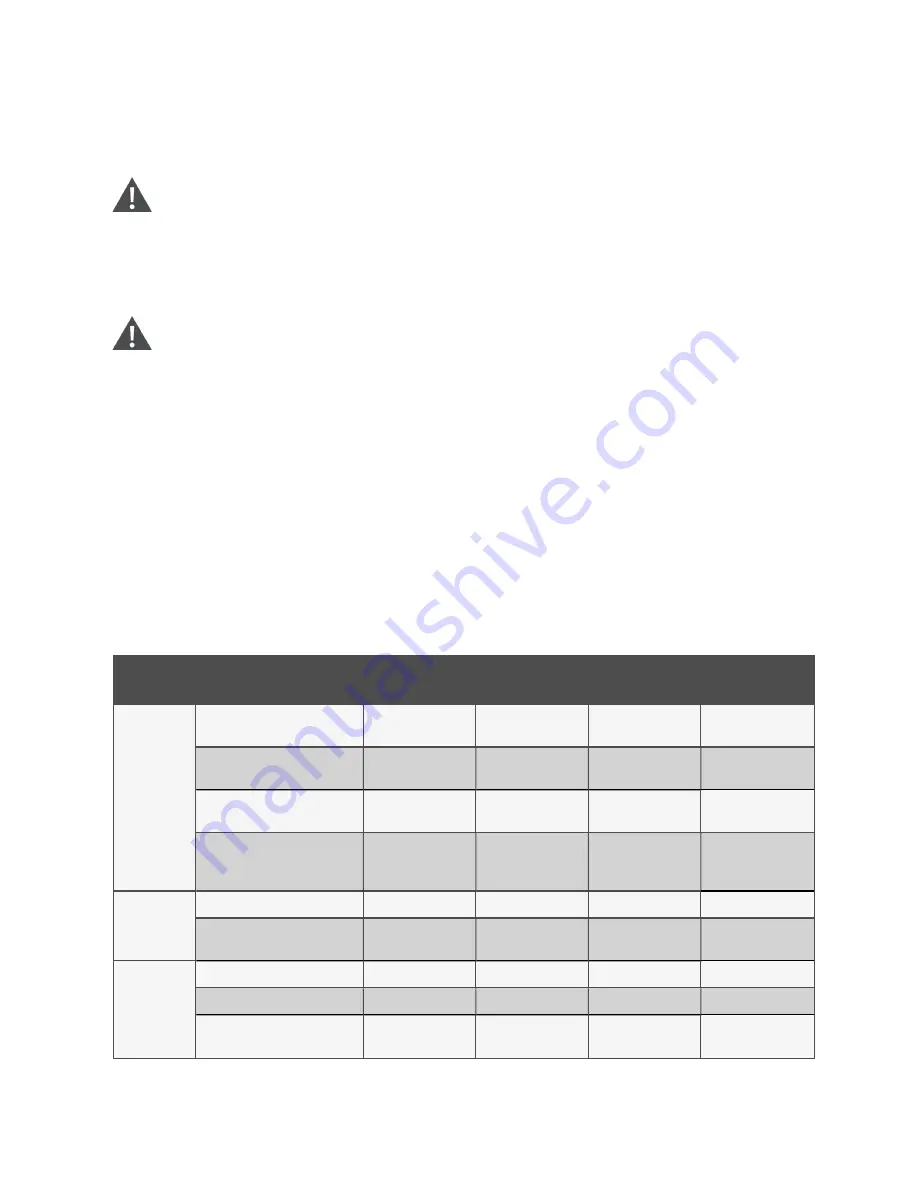

9.1 Maintenance Schedule

Conduct monthly, quarterly, biannual and annual checks according to the following guidelines.

Component

Check Items

Maintenance Period

Monthly by user

3 months

6 months

1 year

General

Check unit/remote display for

clogged-filter warning

X

Check for irregular noise from unit

fans

X

Check for irregular noise from

compressor

X

Check for irregular noise from

remote condenser fans (if

applicable)

X

Filters

Check the state of filters

X

Clean or replace air filters if

necessary

X

Fan

Verify that impellers move freely

X

Check bearings

X

Check that motor supports are

fixed securely

X

9 Maintenance

61

Vertiv™ Liebert® CRV CRD25 and CRD35 Row-Based Cooling System User Manual