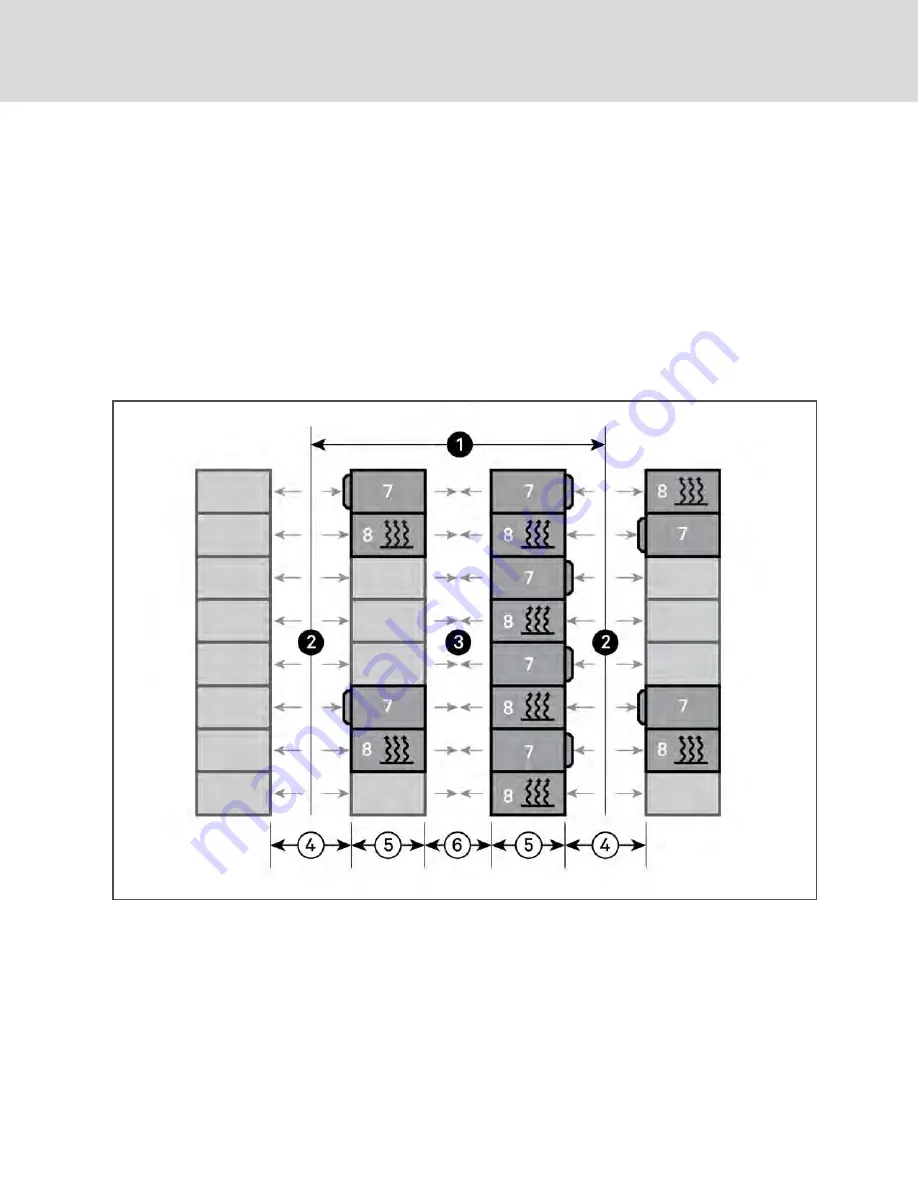

3.3 Implementing a Hot Aisle/Cold Aisle Equipment Layout

Best practice is to place equipment racks in alternating rows of cold aisles and hot aisles. This is best accomplished when

planning the layout of the file server farm area. It is more difficult to accomplish when the computer room is already

populated with operating hardware.

In the cold aisle, the equipment racks are arranged face-to-face so the cooling air discharged from the cooling unit is

discharged up through perforated floor tiles, drawn into the face of the computer hardware and exhausted out the back of

the equipment rack into the adjacent hot aisles. Hot aisles are literally hot because the alternating cold and hot-aisle design

separates the source of cooling air from hot air discharge, which returns to the computer room cooling unit. No perforated

tiles should be placed in the hot aisles, which mixes hot and cold air, lowering the temperature of the air returning to the

cooling units and reducing usable capacity.

Figure 3.1 XDU Layout in Hot/Cold Aisle Application

Vertiv | XDU™ Liquid to Air Heat Exchanger for Chip Cooling

12

Summary of Contents for Liebert XDU 060

Page 1: ...Liebert XDU Liquid to Air Heat Exchanger for Chip Cooling Installer User Guide 600 mm Wide ...

Page 10: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling 6 This page intentionally left blank ...

Page 38: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling 34 ...

Page 74: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling ...