05_01

Warnings (05_01)

WARNING

IT IS RECOMMENDED THAT "ORIGINAL PIAGGIO SPARE PARTS" BE USED,

AS THESE ARE THE ONLY ONES OFFERING YOU THE SAME QUALITY AS-

SURANCE AS THOSE INITIALLY FITTED ON THE VEHICLE.

IT SHOULD BE REMEMBERED THAT USING NON-ORIGINAL SPARE PARTS

CAUSES YOUR WARRANTY RIGHTS TO EXPIRE.

WARNING

PIAGGIO MARKETS ITS OWN LINE OF ACCESSORIES THAT ARE RECOG-

NISED AND GUARANTEED FOR USE. IT IS THEREFORE ESSENTIAL TO CON-

TACT AN AUTHORISED DEALER OR SERVICE CENTRE IN ORDER TO CHOOSE

AND FIT ACCESSORIES CORRECTLY. THE USE OF NON-ORIGINAL ACCES-

SORIES MAY AFFECT THE STABILITY AND OPERATION OF YOUR VEHICLE

AND REDUCE SAFETY LEVELS WITH POTENTIAL RISKS FOR THE RIDER.

82

5 Spare parts and accessories

Summary of Contents for LXV 125 ie 2013

Page 4: ...4 ...

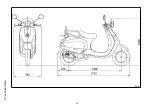

Page 7: ...Vespa LXV 125 ie Chap 01 Vehicle 7 ...

Page 8: ...01_01 8 1 Vehicle ...

Page 10: ...01_02 Analogue instrument panel 01_02 A Fuel gauge 10 1 Vehicle ...

Page 23: ...Vespa LXV 125 ie Chap 02 Use 23 ...

Page 36: ...36 2 Use ...

Page 37: ...Vespa LXV 125 ie Chap 03 Maintenance 37 ...

Page 59: ...03_29 03_30 03_31 59 3 Maintenance ...

Page 74: ...74 3 Maintenance ...

Page 75: ...Vespa LXV 125 ie Chap 04 Technical data 75 ...

Page 76: ...04_01 76 4 Technical data ...

Page 81: ...Vespa LXV 125 ie Chap 05 Spare parts and accessories 81 ...

Page 83: ...Vespa LXV 125 ie Chap 06 Scheduled maintenance 83 ...