−

Place the mixer drive gear with the rounded edge

facing the crankcase bearing.

−

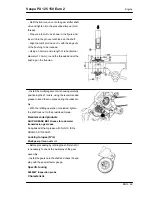

Correctly position the woodruff key inside its

housing.

−

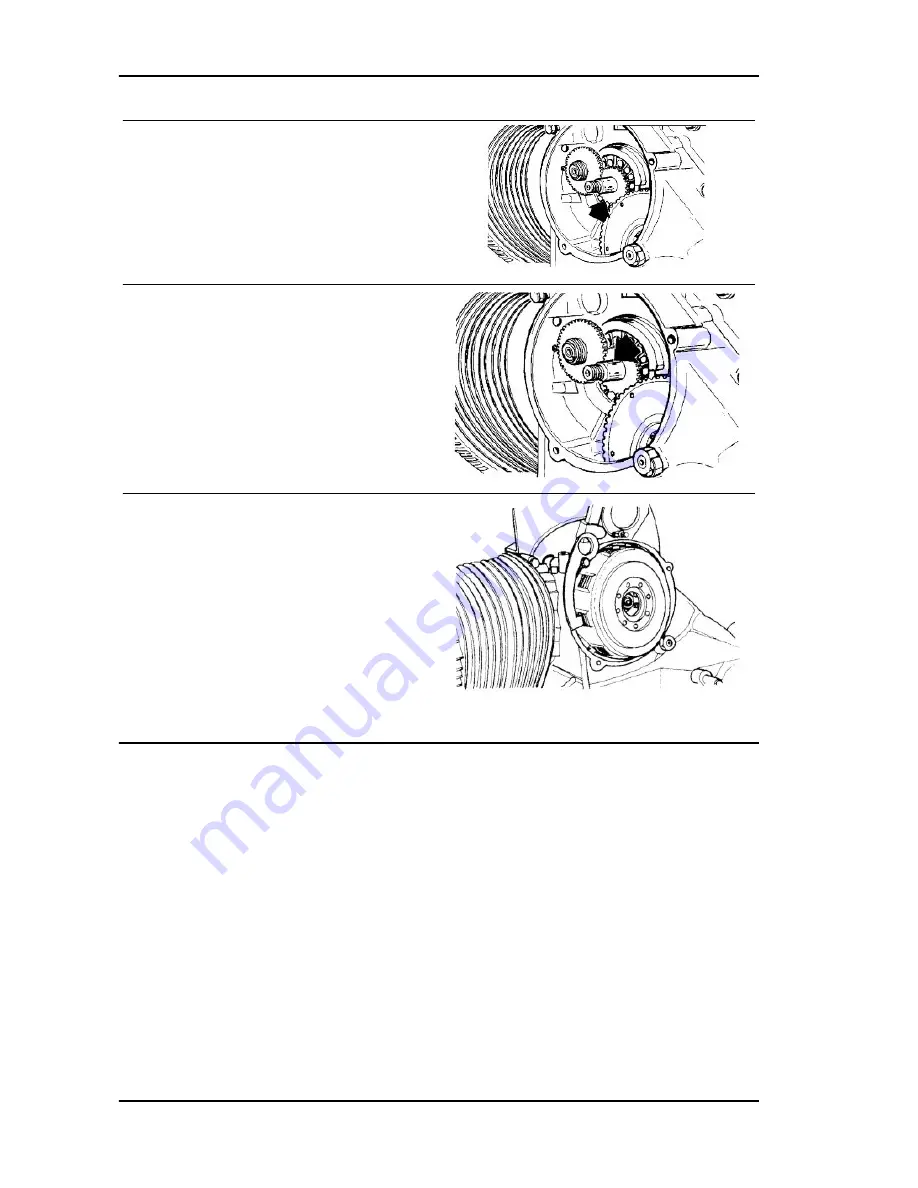

Refit the clutch assembly onto the engine and

tighten the locknut using the special retainer.

−

Refit the remaining components in following the

procedures carried out from their removal in the

reverse order.

Specific tooling

001729Y

Clutch retaining tool

Locking torques (N*m)

Clutch assy. fixing nut

40 ÷ 45

Engine

Vespa PX 125 150 Euro 2

ENG - 72

Summary of Contents for PX 125 150 euro 2

Page 1: ...WORKSHOP MANUAL 633241 Vespa PX 125 150 Euro 2 ...

Page 2: ...WORKSHOP MANUAL Vespa PX 125 150 Euro 2 ...

Page 4: ......

Page 6: ...INDEX OF TOPICS CHARACTERISTICS CHAR ...

Page 18: ...INDEX OF TOPICS TOOLING TOOL ...

Page 25: ...INDEX OF TOPICS MAINTENANCE MAIN ...

Page 35: ...INDEX OF TOPICS ELECTRICAL SYSTEM ELE SYS ...

Page 49: ...INDEX OF TOPICS ENGINE FROM VEHICLE ENG VE ...

Page 52: ...INDEX OF TOPICS ENGINE ENG ...

Page 73: ...INDEX OF TOPICS SUSPENSIONS SUSP ...

Page 83: ...INDEX OF TOPICS BRAKING SYSTEM BRAK SYS ...

Page 89: ...INDEX OF TOPICS CHASSIS CHAS ...

Page 96: ...INDEX OF TOPICS PRE DELIVERY PRE DE ...

Page 99: ...INDEX OF TOPICS TIME TIME ...