2021.A

3

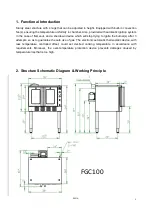

3. Basic Features & Parameters

Model

FGC100 Gas

Convection Oven

FGC200 Gas

Convection Oven

Dimension (mm)

970×1060×1450

970×1240×1450

Cavity Size (mm)

730×650×500

730×830×500

LPG

Pressure (Pa)

2800

2800

Power (kW)

15.8

17.6

Gas Cons. (kg/h)

1.31

1.46

NG

Pressure (Pa)

2000

2000

Power (kW)

15.8

17.6

Gas Cons. (m

3

/h)

1.67

1.86

Gas Inlet Size

NPT 3/4"

NPT 3/4"

Voltage (V)

120V 60Hz

120V 60Hz

N/W (kg)

183

201

Hint: This appliance is only applicable for NG or LPG.

4. Precautions & Recommendations

4.1 Installment

1. Before beginning the installation, remove the packaging. A few parts are protected with an

adhesive film, which should be removed carefully. Remove any glue residual with the proper

substances, such as petrol; never use abrasive substances.

2. Mount the unit feet; the unit must be leveled; small differences of height can be solved by

adjusting the feet.

3. The connections to the gas and/or electric network must be close to the appliance and easy to

reach.

4. We recommend placing the unit under a suction hood so that vapor can quickly evacuate.

5. Install the unit at least 5cm from the wall if the wall does not bear a minimum temperature of

150

℃

(see Fig.1). If the unit is placed very close to the wall, partition walls, kitchen cabinets,

decorative walls, etc., we recommend that they are made with a non-combustible material with a

proper thermal insulation. Pay a lot of attention to regulations concerning fire prevention.