2021.A

4

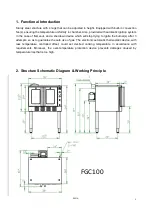

Fig.1

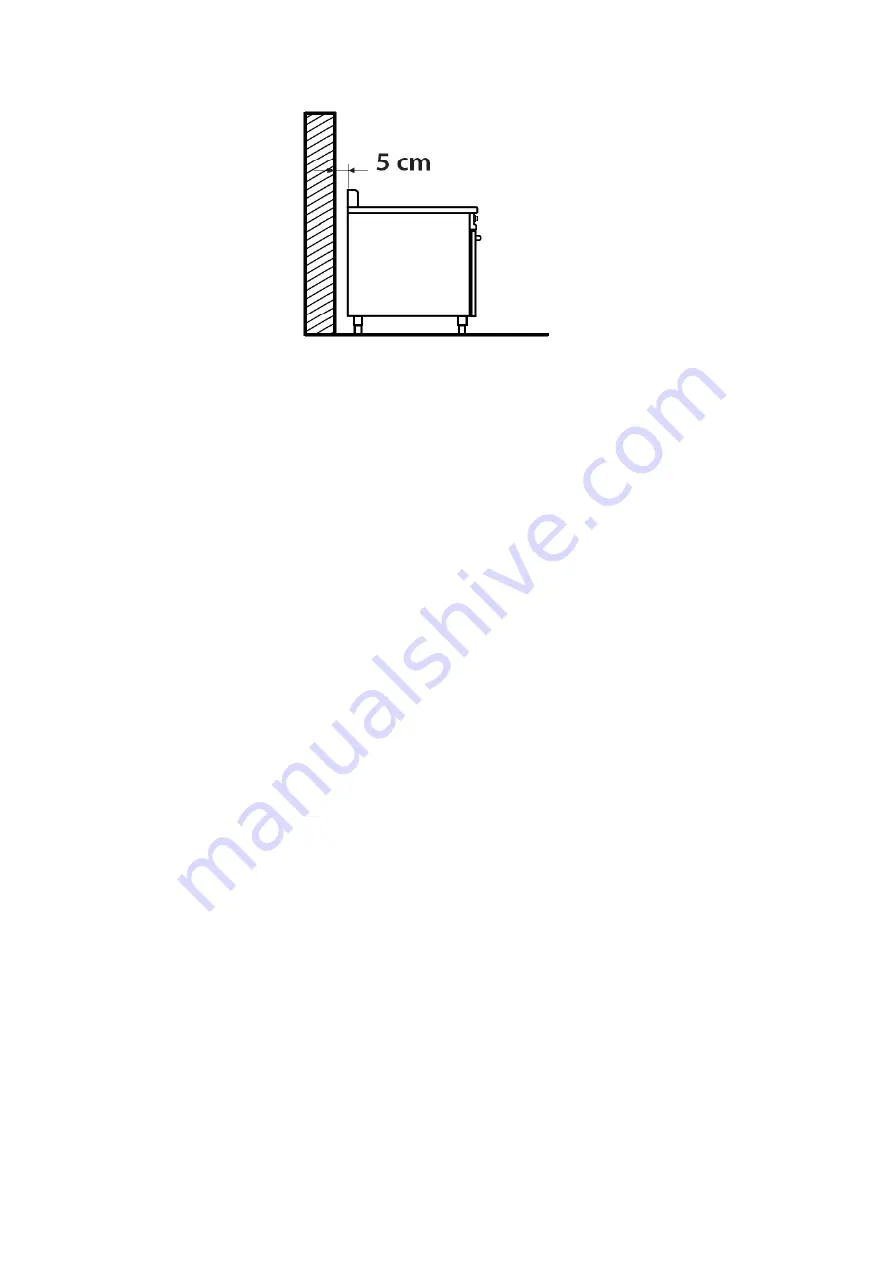

Attention:

➢

Air necessary for the burner combustion is equal to 2 cum/h per each kW of installed power.

➢

Do not locate the oven adjacent to any high heat or grease-producing piece of equipment, such

as a range top, griddle, fryer, etc., that could allow radiant heat to raise the exterior temperature

of the oven above 130

℉

(

54

℃

)

. Do not mount above other cooking equipment.

6.

Law provisions, technical regulations and directives:

The manufacturer declares that the

appliances comply with the EEC directives and the particular reference regulations. The

manufacturer requires the installation to be performed according to the regulations in force.

Before installing, check that the following provisions are met:

⚫

Building regulations and local fire prevention measures

⚫

Accident prevention regulations in force

⚫

Local Gas Board regulations

⚫

Local electric energy supply Board regulations

7.

Running the appliance on other types of gas:

To change over to another type of gas, for

example from methane to liquid, use the correct type of nozzles for the burner in accordance to

the

“Burners” table. The burner nozzles for different types of gas, marked in 100ths of a mm, are

in a case supplied with the appliance. When the appliance has been transformed or adapted,

recheck its functions as described in the

“Checking the functions” paragraph. After the appliance

has been transformed or adapted, specify the new gas type on the plate.

8.

Checking the functions:

Start the appliance; check the gas pipes for leaks; check the burner

flame, even at the minimum.

9.

Notes for the installer:

⚫

Explain and demonstrate how the appliance works to the user according to the instructions,

and hand him the user

’s manual.

⚫

Remind the user that, in the event of any structural alterations or modifications to the room

that houses the appliance, the appliance functions must be rechecked.