EN - 14

EN

replacing the corresponding injectors and

adjusting the minimum flame length suitable

to the gas in use. For this purpose, the

following steps should be performed.

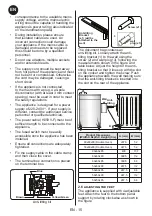

Changing injectors

Hob burners

•

Cut off the main gas supply and unplug

the appliance from the mains electrical

supply.

•

Remove the burner caps and the

adapters.

•

Use a 7 mm spanner to unscrew the

injectors.

•

Replace the injector with the ones from

the gas conversion kit, with the correct

diameters for the type of gas that is

going to be used, according to the gas

injector table.

Adapter

Spanner

Adapter

Cup

Burner

cap

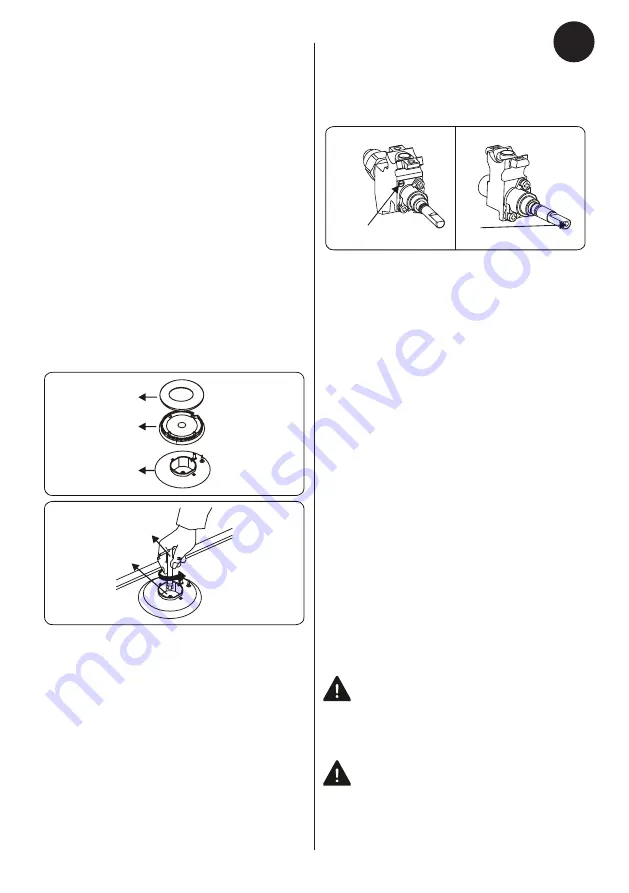

Adjusting the minimum flame position:

First of all, make sure that the appliance

is unplugged from the mains electrical

supply and that the gas feed is open. The

minimum flame position is adjusted with a

flat screw located on the valve. For valves

with a flame failure safety device, the

screw is located on the side of the valve

spindle as shown in the figures. For valves

without a flame failure safety device, the

screw is located inside the valve spindle

as shown in the figure. To make adjusting

the flame position easier, we recommend

that you remove the control panel (and the

micro switch if your model has one) during

the alteration. The bypass screw must be

loosened for conversion from LPG to NG.

For conversion from NG to LPG, the bypass

screw must be tightened.

Bypass screw

Screw(inside the hole)

Valve with flame failure

device

Valve with flame failure

device

Determining the minimum flame position

To determine the minimum position, ignite

the burners and leave them on in the

minimum position. Remove the knobs

because the screws are accessible only

when the knobs are removed. With the help

of a small screwdriver, fasten or loosen the

bypass screw by around 90 degrees. When

the flame has a length of at least 4mm,

the gas is well distributed. Make sure that

the flame does not die out when passing

from the maximum position to the minimum

position. Create an artificial wind with your

hand towards the flame to see if the flames

are stable.

Changing the gas inlet

For some countries, the gas inlet type

can be different for NG/LPG gases. In

this case, remove the current connection

components and nuts (if any) and connect

the new gas supply accordingly. In all

conditions, all components used in gas

connections should be approved by local

and/or international authorities. In all gas

connections, refer to the “Assembly of

gas supply and leakage check” clause

explained above.

2.5

eleCtriCal ConneCtion

anD Safety (if available)

WARNING:

The electrical connection

of this appliance should be carried out

by an authorised service person or

qualified electrician, according to the

instructions in this guide and in compliance

with the current local regulations.

WARNING: THE APPLIANCE MUST

BE EARTHED.

•

Before connecting the appliance to the

power supply, the voltage rating of the

appliance (stamped on the appliance

identification plate) must be checked for

Summary of Contents for VC-993wnPBG

Page 19: ...EN 18 EN VC 993wnPBR Mode Professional...

Page 33: ...EN 32 EN...

Page 52: ...PL 19 PL VC 993wnPBR Mode Professional...

Page 87: ...SI 18 SI VC 993wnPBR Mode Professional...

Page 101: ...SI 32 SI...

Page 102: ......

Page 103: ......

Page 104: ......