27

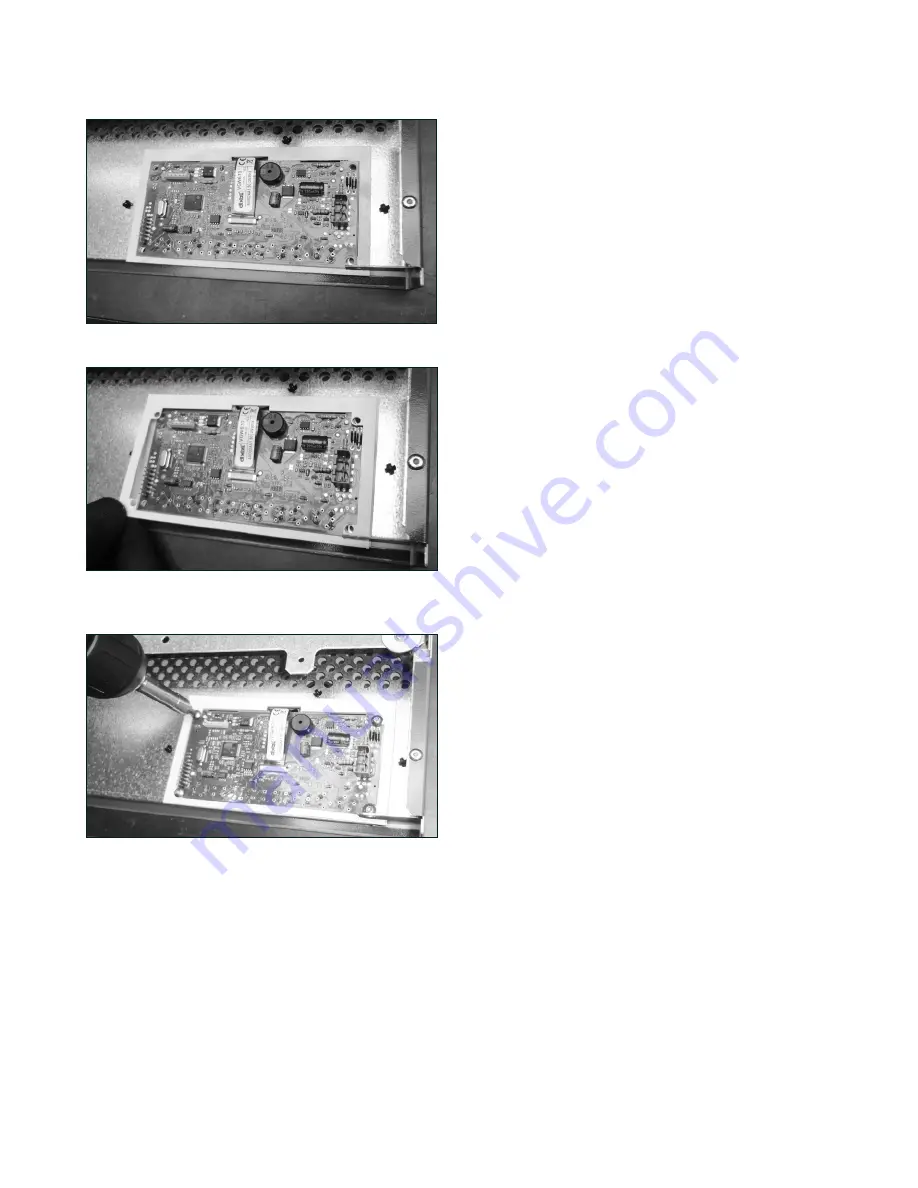

10. Then put on the new print board.

11. The second plastic part is placed on the

print board.

12. Put in the screws in each corner.

13. Make sure that all 6 buttons are placed

correctly on the front of the toppanel by

pushing each button (click).

14. Close the top panel and place the

screws and the locking pawl.