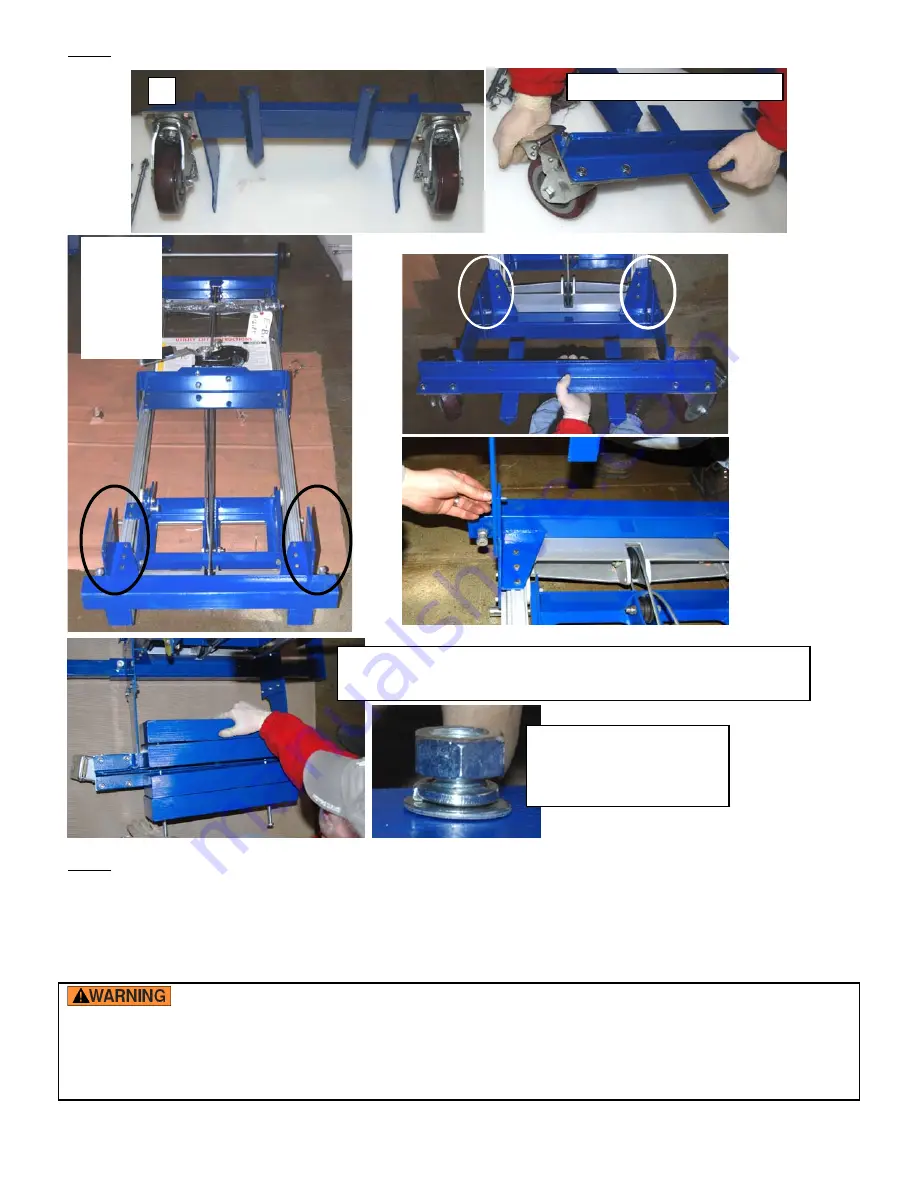

Step 2: Attach the weldment to the main assembly.

Step 3: Install and position the forks by following R & S model fork installation steps 3 & 4 on p. 8.

Operation Instructions:

- 9 -

The operating instructions in this manual are meant to

supplement

the operation recommendations of ITSDF

standard B56.10-2006. According to the standard, the A-Lift is a, “Manually propelled high lift industrial truck”. Safe

operation of this type of device is the operator’s responsibility.

DO NOT operate the winch lift until you read AND understand all of the instructions. If you do not

understand an instruction, contact Vestil for clarification.

•

Review ALL of the safety guidelines on p. 5 before each use;

•

ALWAYS use proper lifting techniques;

•

Enlist a coworker to help you lift, load, and unload the A-lift;

•

DO NOT use the lifter on stairs.

g.

Fasten the bolts in

place using a flat washer,

followed by a lock washer

and then a nut.

f.

Set the four counterweights on the weldment; then insert the

counterweight retaining bolts beginning with the outermost weight.

e.

Bolt

the

weldment to

the main

assembly, and

then secure

the bolts with

nuts.

d.

Align the

bolt holes in

the weldment

with the holes

present in the

weldment

brackets

(circled in

photos c & d).

c.

Lay the

main

assembly

- winch

side up -

on the

ground.

b.

Lock both of the castors

a