Rev. 6/16/2020

BOL-G MANUAL

Copyright 2020 Vestil Manufacturing Corp. Page 4 of 5

RECORD OF SATISFACTORY CONDITION (the “RECORD)

After installing the bollard, make a record of its appearance. Describe in writing the condition of the

bollard, anchoring hardware and the anchoring surface around the bollard, operating mechanisms (if

applicable), as well as the location of each label, tag, decal, etc. Take photographs of all frame

elements (mounting plate, bollard body, cap). Add the photos to the record.

These documents and

photos are a record of the unit in satisfactory condition

.

INSPECTIONS AND MAINTENANCE

When conducting the following inspections, compare your observations to the

determine if a component is in satisfactory condition. Do not use the product unless every component

is in satisfactory condition. Cosmetic changes, like damaged paint/powder coat do not constitute

changes from satisfactory condition. However, touchup paint should be applied to all affected areas as

soon as damage occurs. Contact

to order replacement parts. Contact

information appears on the cover page of this instruction manual.

At least once per month:

1. Check the surface of the product for dirt or other matter. Clean the surfaces.

2. Examine anchoring hardware. Replace damaged, worn, or corroded hardware. Confirm that the

bollard is solidly anchored to the (concrete) ground surface. Replace all anchoring hardware that is

not solidly attached to the ground. If the bollard wobbles, tighten loose anchor bolts. The bollard

should not wobble. Install the bollard in another location if wobble cannot be eliminated in the

present location.

3. Examine frame elements for excessive wear, breakages, corrosion/rusting, damage, and metal

fatigue.

4. Check all labeling. Replace labels that are damaged or not easily readable. See

5. Examine the whole structure for severe rusting/metal erosion, rot, thinned regions. If rusting is

purely superficial, remove the rust/corrosion with a steel bristle brush or steel wool. Clean the

affected area and apply touchup paint. If rusting, rot, or thinning has weakened the material, contact

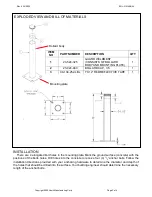

LABELING DIAGRAM

The unit should be labeled as shown in the diagram. However, label content and locations are

subject to change so your product might not be labeled exactly as shown. Replace all labels that are

damaged, missing, or not easily readable (e.g. faded). To order replacement labels, contact the

technical service and parts department online at

http://www.vestilmfg.com/parts_info.htm

. Alternatively,

you may request replacement parts and/or service by calling (260) 665-7586 and asking the operator to

connect you to the Parts Department.

252