rev. 11/1/2016

CB-PMPS, manual.doc

Copyright 2016 Vestil Manufacturing Corp. Page 19 of 23

5

.

"Spongy·

or "Jerky· unit operation.

s

.

Fluid starvation

.

t. Air in system

.

s

.

See 2

(d),

(f)

,

(g), (j)

t

.

See air bleed procedure (p. 19).

6.

Unit lowers too slowly when loaded

.

u. Lowering solenoid valve filter screen

clogged.

v. Pinched tube or hose

.

w

.

Foreign material in flow control valve.

x. Binding cylinders

.

y. Foreign material in velocity fuse.

u

.

Remove lowering solenoid valve and

clean filter screen.

v. Correct as necessary.

w

.

Remove and clean flow control valve.

Refer to Hydraulic System Diagram on p.

3)

.

x

.

Align cylinders correctly.

y. Remove and clean velocity fuse. Refer

to Hydraulic System Diagram on p. 3)

.

7

.

Unit lowers too quickly

.

z. Foreign material stuck in flow control

valve.

(In

this case, carriage initially lowers

at a normal rate but accelerates as the

carriage descends).

z. Remove flow control valve from the

valve block and clean. (Refer to Hydraulic

System Diagram on p. 3)

.

8.

Unit raises then lowers slowly.

aa

.

Lowering solenoid valve may be

incorrectly wired or is stuck open

bb. Check valve may be stuck open.

cc. Check for leaking hoses, fittings, pipes

.

dd

.

Cylinder packings may be worn or

damaged

.

aa

.

See 3 (a)

.

bb. Remove and clean check valve

;

(Refer

to Hydraulic Section of Owner's Manual)

.

cc. See 2 (c).

dd

.

Replace packings

(contact

factory for

replacement parts).

9.

Carriage elevates, but does not lower

.

ee. Incorrect lowering solenoid valve

wiring

.

ff

.

Lowering solenoid valve

i

s stuck.

gg. Faulty lowering solenoid coil.

hh. Binding cylinders.

ii. If the carriage lowers too rapidly, air is

present in the hydraulic system causing the

velocity fuse to activate and shut off the oil

flow from the cylinders

. Consequently,

the

deck will not lower.

ee

.

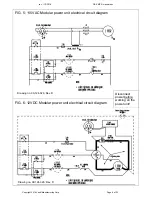

Correct per diagram (p. 8-10)

.

ff

.

Lightly tap down the solenoid coil body

to seat it properly

.

(DO NOT hit coil hard as

it will permanently damage the internal

system

.

DO NOT remove the solenoid

valve from the block because

the

carriage

will descend dangerously quickly.

gg

.

Remove and replace. DO NOT remove

the down solenoid valve fro the block as

the unit will come down at a dangerous

speed.

hh

.

See 4 (c).

ii

.

To unlock, re-pressurize the hydraulic

system.