Rev. 4/22/2019

FMDL MANUAL

Copyright 2019 Vestil Manufacturing Corp.

Page 12 of 16

original condition. Purely cosmetic changes, like damaged paint or powdercoat are not changes from original

condition. However, touchup paint should be applied to all affected areas as soon as the finish is damaged.

Inspections & Maintenance:

Regular inspections and maintenance are necessary for the lifter to remain in normal condition. Before using it

for the first time, create a written record that describes the appearance of the drum gripping mechanism, drum

cradle, pins, fork pockets, the safety chain, and the frame. Install the lifter on the forks of your forklift and use it to lift

a drum.. Record your observations about how the gripping mechanism engages the drum. Lower the drum and

record your observations. This written record establishes “normal condition”. When conducting future inspections

compare those observations with the written record to determine whether a component is in normal condition or

requires repair or replacement.

Before each use, inspect the following components:

1. Safety chain and snap hook (attached to the free end of the safety chain): confirm that the spring latch

automatically closes securely against the hook. DO NOT use the lifter if the hook, chain, cold shut (the loop

welded to the lifter frame, which connects to one end of the chain), or ratchet strap loop castings are damaged.

2. Labels: all labels should be readable and located as shown in the

. If a label is unreadable or

missing, contact the

At least once per month, inspect:

1. Fasteners (hardware):

Bolts, nuts, washers, pins, cotter pins;

Chain and snap hook.

2. Fork pockets: confirm that each pocket is structurally sound, i.e. no significant corrosion. Do not use the lifter if

the fork pockets are structurally unsound

3. Welds: confirm that all welds are intact.

4. Drum grippers, Eagle Beak® upper and/or lower jaw, fork pockets, and supporting frame: must be undamaged.

For example, no deformations, warps, or cracks.

5. Overall condition of drum lifter: the structure should be clean, square and rigid, and free of rust and corrosion.

Remove dirt and debris. Do not use the lifter if the supporting frame and/or one or both grippers are excessively

rusted or corroded.

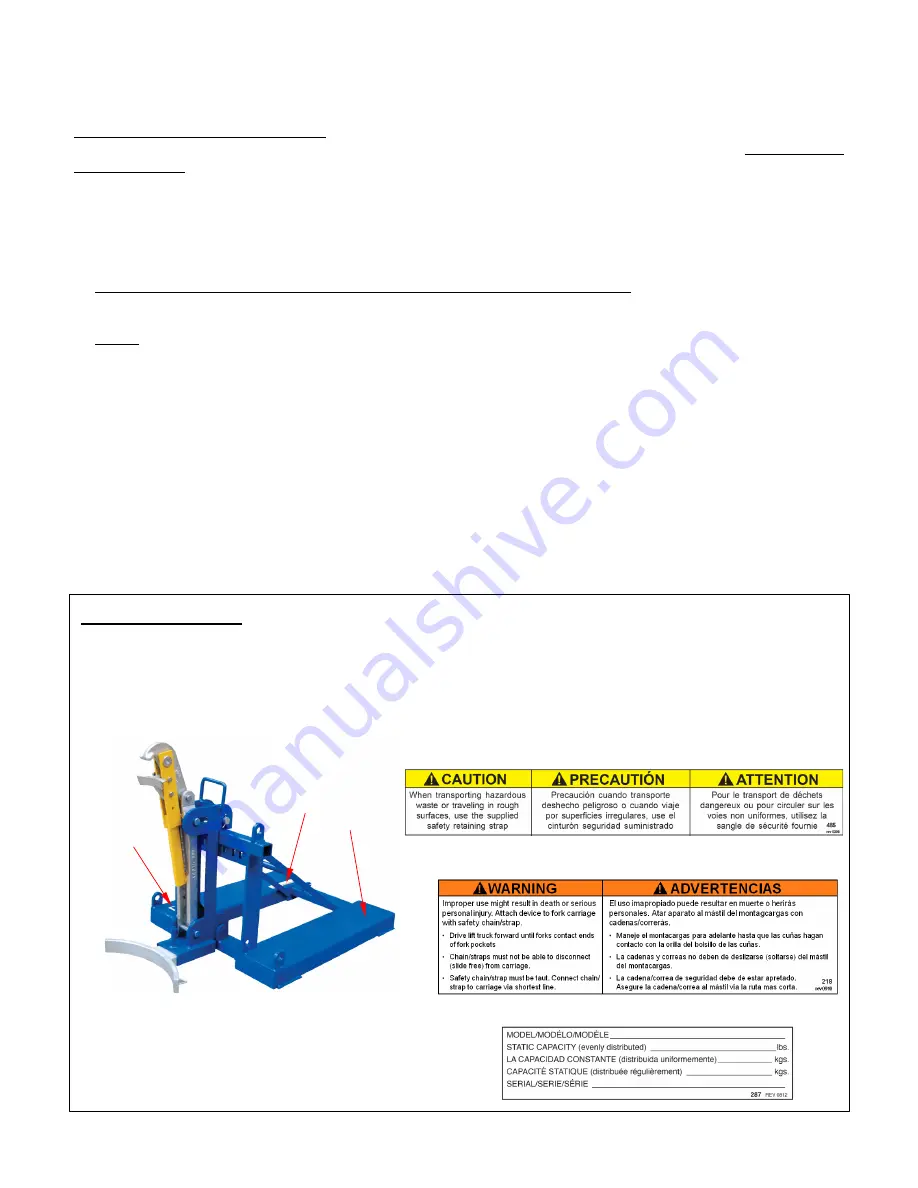

Labeling diagram:

The unit should be labeled as shown in the diagram. However, label content and location are subject to

change so your product might not be labeled exactly as shown. Compare this diagram to your

. Replace all labels that are damaged, missing, or not easily readable (e.g. faded). Order replacement

http://www.vestilmfg.com/parts_info.htm

Alternatively, you may request replacement parts and/or service by calling (260) 665-7586 and asking the

operator to connect you to the Parts Department.

B: Label 218 (on fork pocket)

B

C

C: Label 287 (on fork pocket)

A

A: Label 485

A