Rev. 2/4/2021

DKL, MANUAL.doc

Copyright 2021 Vestil Manufacturing Corp. Page 9 of 10

RECORD OF SATISFACTORY CONDITION (THE “RECORD”)

Before putting the ladder into service, record its condition. Make written records that describe the locations of

labels and the soundness of all anchor bolt connections. Take photographs from multiple angles. Take close-range

photographs of all anchor bolts, each mounting bracket, each label, and all bracket fasteners (bolts, lock nuts). Collect

all photographs and writings in a file and mark the file appropriately to identify it. This file is a record of the ladder in

satisfactory condition. Use the contents of this file to determine whether the ladder is in satisfactory condition during

all inspections. Do not use the ladder unless it is in satisfactory condition. Purely cosmetic changes, like damaged

finish (paint or powder coat), do not constitute changes form satisfactory condition. However, touchup paint should be

applied to the affected areas as soon as damage is noticed.

NATIONAL STANDARDS

This product is a fixed ladder (FL).

(the “Standard”) applies to FL’s. You

should

acquire

a copy of the latest version of the Standard. Follow all use and maintenance/care instructions provided in the

Standard as well as all other provisions for FL owners and users. If any content in this manual conflicts with any

mandatory provision(s) in the Standard, apply the provision(s) from the Standard. Please contact

personnel and report the conflict.

INSPECTIONS & MAINTENANCE

Regular inspections and maintenance is required for the ladder to function properly for as long as possible. Inspect

the unit as instructed. Inspections and all necessary repairs should only be performed by qualified persons. Compare

the results of each inspection to the

. Do not use the ladder unless every

part is in satisfactory condition. If you have any questions about the condition of your ladder, contact the

department. The phone number is provided on the cover page of this manual.

Never make temporary

repairs of damaged or missing parts

. Only use manufacturer-approved replacement parts to restore the ladder to

satisfactory condition.

Before each use

inspect the ladder for any sustained damage, such as unusual wear, deterioration, or corrosion.

Look for loose connections. Tighten all loose connections.

Regular inspections

—

At least once per month

inspect the following items. Replace all parts not in satisfactory

condition before returning the ladder to service. DO NOT continue to use the ladder if damage cannot be repaired.

•

Frame elements (siderails and rungs): Inspect both siderails. Confirm that they are solidly fastened to the rungs

and to the wall. Each siderail and each rung/step should be straight, rigid, and undamaged. Look for excessive wear,

bends, cracks, damaged welds, and looseness. All frame elements should be square, rigid, and free of rust and

corrosion. Remove rust and apply touch-up paint to the affected area. Check the areas where components are

fastened/bolted together. Check all fasteners (bolts, lock nuts) for damage. Examine the metal around bolt holes for

cracks, elongations, etc. All rung fasteners must be tight. If a lock nut must be removed, it must be replaced with a

new lock nut.

•

Anchor bolts: Examine the anchor bolts and the wall material around the anchor bolts. Bolts must be solidly

attached to the wall. The wall material must not be cracked or damaged in other ways around the anchor bolts.

Maintenance

: In addition to correcting issues discovered during inspections, maintain the ladder.

•

Clean the ladder with a damp cloth to remove dirt and grime, especially from step surfaces. Let the ladder dry

completely before returning it to service.

•

Apply touchup paint wherever the finish is damaged. Apply touchup paint as soon as damage occurs.

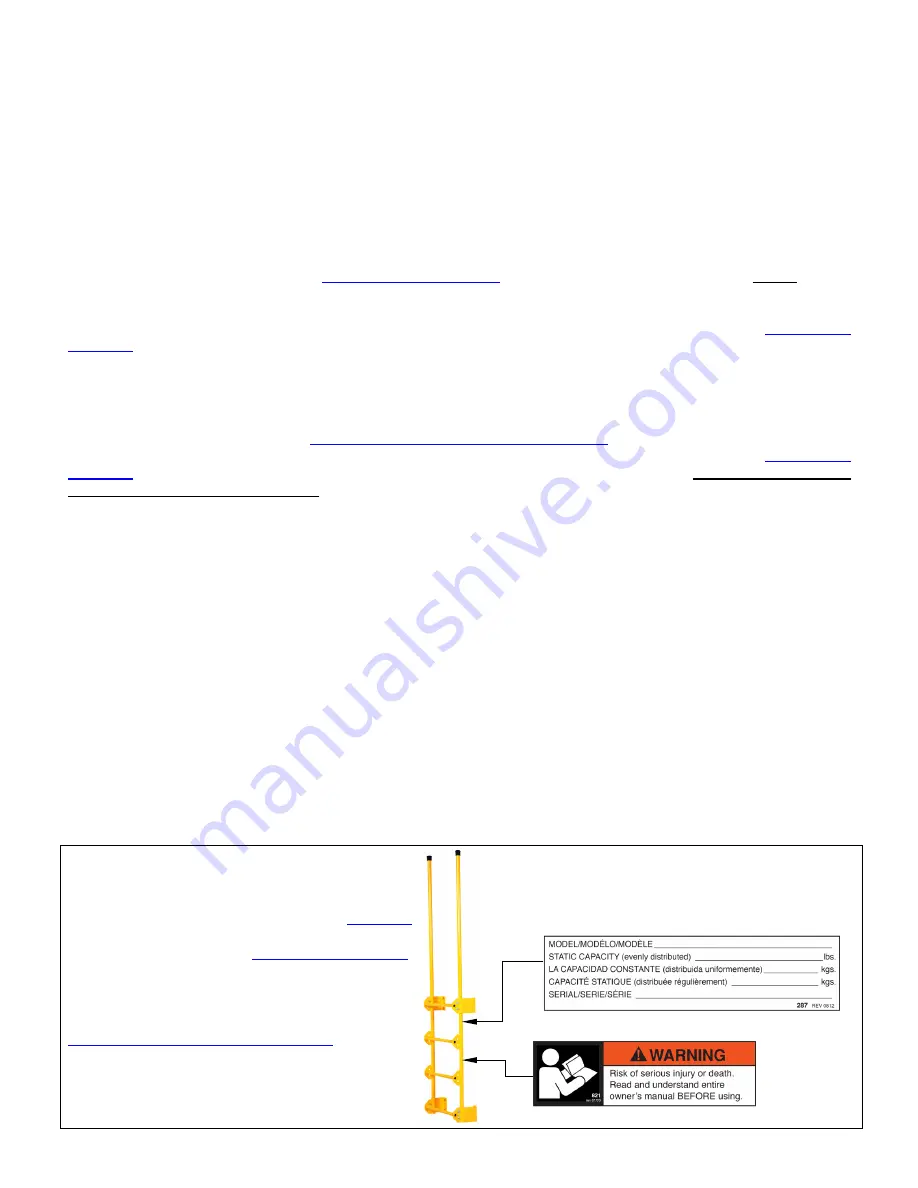

LABELING DIAGRAM

Label content and location are subject to

change. Your product might not be labeled exactly

as shown. Compare this diagram to the

on p. 9

.

If differences exist between the diagram

and the

RECORD,

contact

Replace all labels that are damaged, missing, or

not easily readable (e.g. faded). To order

replacement labels, contact the technical service

and parts department online at

http://www.vestilmfg.com/parts_info.htm

Alternatively, you may request replacement parts,

including labels, and/or service by calling (260)

665-7586 and asking the operator to connect you to

the Parts Department.

Label 287: Model designation and capacity;

covered with label 770

Label 821: Read instruction manual