the forks don't lower.

C - If the jack don't descend when control lever (part # 1) is in the LOWER position, turn the nut (part # 18)

clockwise until raising the control lever (part # 1) lowers the forks. Then check the DRIVE position according to

item A and B to be sure the nut (part # 18) is in the proper position.

D - If the jack don't elevate while pumping in the RAISE position, turn the nut (part # 18)

counter-clockwise until the jack elevate while pumping in the RAISE position. Then check the

LOWER and DRIVE position according to item A,B, & C.

Maintenance and repair

T

ROUBLESHOOTING

G

UIDE

--

______

Warning: Before performing any task, always block drive wheel off of the ground.

Consult the factory for problems at time of installation, or for any problems not addressed below.

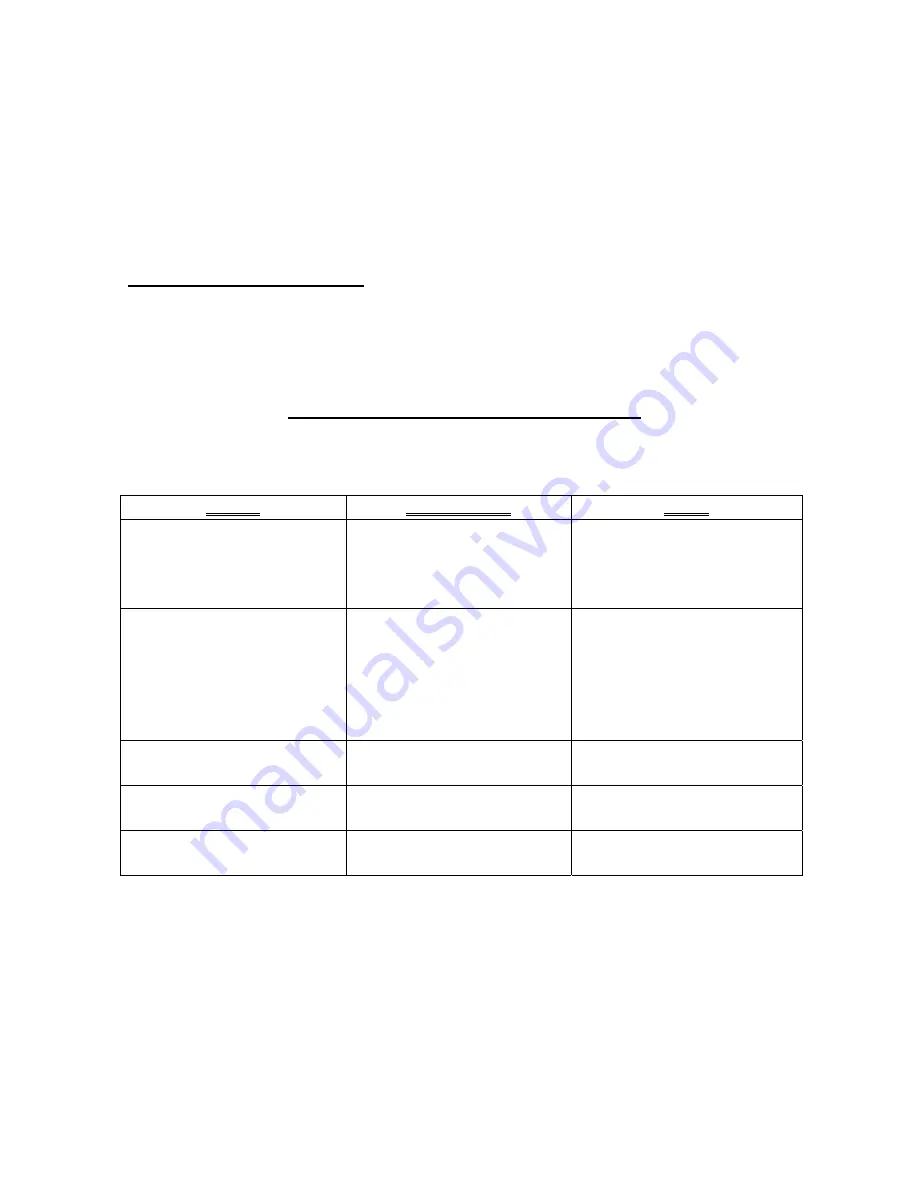

Problem: Possible

cause(s): Action:

Lifting height is not longer achieved

Hydraulic oil level is too low

Re-fill hydraulic oil when carriage is

all the way down.

Unit jerks when lifting

Air in the system

Open vent screw on the lift cylinder

with carriage lowered all the way

down. Lift carriage with vent screw

open until oil is free from air bubbles.

Close the vent screw

Carriage can’t be lifted up

Without hydraulic oil

Oil has impurities

Fill the oil

Change the oil

Carriage can’t be lowered

Oil has impurities

Piston rod & pump body is deformed.

Change the oil and clean drift valve

Replace piston rod or pump body

Oil leakage

Seals worn, cracked or damaged.

Replace with new one.

Summary of Contents for DRUM-55-S

Page 8: ...PARTS DRAWING...