2. TROUBLE SHOOTING

a. Common trouble shooting

If the truck has malfunctions follow the instructions, mentioned in chapter 6.

Table 3: Trouble shooting

TROUBLE

CAUSE

REPAIR

Load weight too high

Battery discharged

Lift only the max. capacity, mentioned on the ID-plate

Charge the battery

Load

can’t

be Lifting fuse faulty

Check and eventually replace the lifting fuse

Check and eventually refill hydraulic oil

lifted

Hydraulic oil level too

low

Oil leakage

Repair the sealing of the cylinder

Oil leakage

from air

Excessive quantity of oil. Reduce oil quantity.

breathing

Charge the battery completely and then remove the

Battery is charging

main power plug form the electrical socket.

Connect the battery correctly

Check and eventually replace fuses

Charge the battery

Battery not connected

Fuse faulty

Truck not

starts

Low battery

operating

Emergency switch is

activated

Turn the emergency clockwise

Tiller in the operating

Move the tiller firstly to the braking zone.

If the truck has malfunctions and

can’t

be operated out of the working zone, jack the truck up and go with

a load handler under the truck and safe the truck securely. Then move truck out of the aisle.

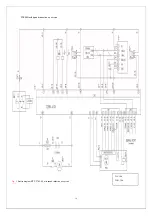

b. Fault code

When

is on, means there is fault of the truck, you can remove the code on LCD with

the help of following table.

5

Summary of Contents for EPT-2745-45

Page 2: ......