Rev. 9/25/2017

HDC-450, MANUAL

Copyright 2017 Vestil Manufacturing Corp. Page 8 of 26

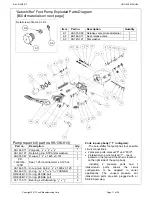

HDC-450-84 Exploded Parts Diagram (Exploded Parts Diagram on p. 7)

Item

Part no.

Description

Qty. Item

Part no.

Description

Qty.

1

09-514-097 Weldment, base with mast

1

17

16-145-031 Bolt with grease zerk,

1

/

2

”-13x3

1

/

2

” 2

2

09-514-095 Weldment, pivot arm

1

18

11129

Hex bolt, gr. A, zinc finish,

3

/

8

”-16 x

48”

2

3

09-538-005 Carriage/saddle drum weldment

1

19

36106

Hex nut, gr. A, zinc plated,

3

/

8

”-16 2

4

09-024-002 Cover, tube cap

1

20

33008

Flat washer, low carbon, USS, zinc

plated,

3

/

8

”

1

5

45286

#11 hitch pin clip,

1

/

8

” x 2

5

/

8

” 3

21

09-516-004-

A3

Bushing, bronze, 37mm long, 20mm

shaft

1

6

09-016-087 Bracket, spacer, cradle arm

1

22

09-516-079 Bracket, weldment, small door

1

7 66173

Clevis

pin,

3

/

4

” x 4

1

/

2

”

1

23

40163

M8-1.25 Nylock nut

1

8

09-516-006 Weldment, swinging door

1

24

38623

HHCS, metric, zinc plated, 8.8

M8x1.25x60mm

1

9 16-132-216

Caster,

wheel,

GFN-8/2-W

2 25 09-002-004-A

3

/

16

” coil chain, 33” long

1

10 37030

1

/

2

”-13 Nylon insert lock nut

2

26

99-021-904-

001

Cylinder, hydraulic, 1

1

/

2

” x 18”

1

11 99-640-005

Hydraulic foot pump, autoshifter, 2-

speed (manual hydraulic units only)

1

27

01-016-018 Pump, manual, base plate

1

12 16-132-350

Floor

lock

1 28

11105

Hex bolt, gr. A, zinc plated,

3

/

8

”-

16x1”

5

13

11119

Hex bolt, gr. A, zinc finish,

3

/

8

”-16 x 4”

1

29

99-612-001 Nut & bolt combo, caster receiver

2

14 33622

Split lock washer, carbon steel,

medium zinc finish,

3

/

8

”

2 30 16-132-021

Caster,

swivel,

PU-5/2-S

2

15 37024

Nylon insert lock nut, gr. 2, zinc finish,

3

/

8

”-16

5

31

13-025-023 Handle, grip, 1

1

/

8

” I.D., red

2

16 09-112-029

Pin,

clevis

2 32

09-516-004-

001

Subassembly, gear train, pull chain

1

33

15-023-001

Reservoir

1

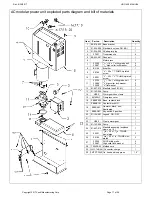

HDC-450-96 Exploded Parts Diagram (Exploded Parts Diagram on p. 9)

Item

Part no.

Description

Qty. Item

Part no.

Description

Qty.

1

09-514-157 Weldment, base with mast

1

17

11129

Hex bolt, gr. A, zinc finish,

3

/

8

”-16 x

48”

2

2

09-514-096 Weldment, pivot arm

1

18

36106

Hex nut, gr. A, zinc plated,

3

/

8

”-16 2

3

09-538-005 Carriage/saddle drum weldment

1

19

16-145-031 Bolt with grease zerk,

1

/

2

”-13x3

1

/

2

” 2

4

09-516-004-

001

Subassembly, gear train, pull chain

1

20

33008

Flat washer, low carbon, USS, zinc

plated,

3

/

8

”

1

5

09-024-002 Cover, tube cap

1

21

09-516-004-

A3

Bushing, bronze, 37mm long, 20mm

shaft

1

6 66173

Clevis

pin,

3

/

4

” x 4

1

/

2

”

1

22

09-516-079 Bracket, weldment, small door

1

7

45286

#11 hitch pin clip,

1

/

8

” x 2

5

/

8

” 3

23

38623

HHCS, metric, zinc plated, 8.8

M8x1.25x60mm

1

8

09-016-087 Bracket, spacer, cradle arm

1

24

40163

M8-1.25 Nylock nut

1

9

09-516-006 Weldment, swinging door

1

25

09-002-004-A

3

/

16

” coil chain, 33” long

1

10 37030

1

/

2

”-13 Nylon insert lock nut

2

26

99-021-904-

001

Cylinder, hydraulic, 1

1

/

2

” x 18”

1

11 99-640-005

Hydraulic foot pump, autoshifter, 2-

speed (manual hydraulic units only)

1

27

01-016-018 Pump, manual, base plate

1

12 16-132-350

Floor

lock

1 28

11105

Hex bolt, gr. A, zinc plated,

3

/

8

”-

16x1”

5

13

11119

Hex bolt, gr. A, zinc finish,

3

/

8

”-16 x 4”

1

29

99-612-001 Nut & bolt combo, caster receiver

2

14 33622

Split lock washer, carbon steel,

medium zinc finish,

3

/

8

”

2 30 16-132-021

Caster,

swivel,

PU-5/2-S

2

15 37024

Nylon insert lock nut, gr. 2, zinc finish,

3

/

8

”-16

5

31

13-025-023 Handle, grip, 1

1

/

8

” I.D., red

2

16

09-112-029 Pin, clevis

2

32

16-132-216 Caster, wheel, GFN-8/2-W

2

33

15-023-001

Reservoir

1