Rev. 5.24.2022

LAD-RAF, MANUAL

Copyright 2022 Vestil Manufacturing

Page 17 of 19

RECORD OF SATISFACTORY CONDITION (THE “RECORD”)

After assembling the ladder and before putting it into service, visually inspect the ladder. Record the

condition and appearance of each of the frame members (step weldment, back leg weldment, base

support frame members), the handrails, outriggers, wheels and/or casters, (leg) caps, back platform frame

and chain, and all fasteners (bolts, nuts, etc.). Thoroughly photograph the ladder from multiple angles.

Include close range photographs of the rubber leg caps, casters and wheels, all labeling, and all handrail

connections. Add the photographs to the record. Collate all photographs and writings into a single file. This

file is a record of the ladder in satisfactory condition. Compare the results of all inspections to this Record to

determine whether the ladder is in satisfactory condition. Do not use the ladder unless it is in satisfactory

condition. Purely cosmetic changes, like damaged paint or powdercoat, are not changes from satisfactory

condition. However, touchup paint should be applied as soon as damage occurs.

NATIONAL STANDARDS

This product is a “mobile ladder stand” (MLS).

(the “Standard”) applies to MLS’s. You

should

acquire a copy of the latest version of the standard. Follow all use and maintenance/care

instructions provided in the Standard as well as all other provisions for MLS owners and users. If any content

in this manual conflicts with any mandatory provision(s) in the Standard, apply the provision(s) from the

Standard.

USING THE LADDER

Review the

Inspect the ladder before each use for damage, such as unusual wear, deterioration, or corrosion.

Tighten loose nuts. If a lock nut has been partially or completely unfastened, it must be replaced with a new

lock nut.

Make sure there are no children in the area where the ladder is used

or stored

.

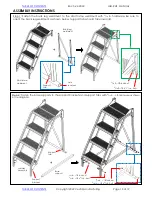

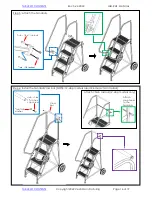

Climbing the ladder:

ONLY use this ladder on solid, level ground. Never use the ladder on angled surfaces. The ladder must

not wobble or lean while in use. Only climb the ladder when the steps and handrails are clean and dry.

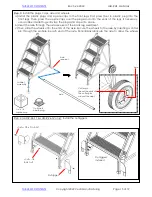

The rubber caps on the front legs must solidly contact the ground. The caps are provided to help the

ladder resist movement during use. Confirm solid contact between the entire bottom surface of each cap

and the floor before climbing the ladder. Do not use the ladder if either or both of the rubber caps are

damaged (worn, cracked, torn, or cut through by the front legs (see

from service until new caps are installed.

Face the ladder and grasp the handrails while ascending or descending the steps. Do not lean against

the handrails, the guardrails (around the top of the ladder), or the cross bar or chain. Do not lean over the

handrails, guardrails, or cross bar.

To move the ladder, grasp either the handrails or the side rails. Carefully lift the front of the ladder off of

the ground. Ladders with more steps are heavier and therefore require more effort to move. Only attempt

to lift and move the ladder if you are able to comfortably lift it and can easily control it.

INSPECTIONS & MAINTENANCE

Inspections and repairs should only be performed by qualified persons. Compare the results of each

(the “RECORD”). Do not use the hopper unless all

parts are in satisfactory condition. Replace parts that are not in satisfactory condition before using the

hopper again.

DON’T GUESS!

If you have any questions about the condition of your hopper, speak with

.

The phone number is provided on the cover page of this manual.

Never

make temporary repairs of damaged or missing parts

. Only use manufacturer-approved replacement

parts. DO NOT continue to use the ladder if damage cannot be repaired.

Before each use

inspect the ladder for any sustained damage such as impact/collision damage, unusual

wear, deterioration, or corrosion. Look for loose connections. Tighten all loose connections. If any lock nut is

removed from its bolt, it must be replaced with a new lock nut.

Regular inspections

—

at least once per month

inspect the following items. Replace all parts not in

satisfactory condition before returning the ladder to service. DO NOT use the ladder if damage cannot be

repaired.

•

Handrails, guardrails, cross bar, snap hooks, and platform chain

: Inspect both handrails. Confirm that they

are solidly fastened to the step weldment and to the platform. Each handrail should be straight, rigid, and

undamaged. Examine the guardrails around the platform for damage, bends, and cracks. Examine the