Rev. 5.24.2022

LAD-RAF, MANUAL

Copyright 2022 Vestil Manufacturing

Page 13 of 19

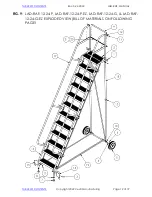

BILL OF MATERIALS

LAD-RAF-12-24-P, LAD-RAF-12-24-P-EZ, LAD-RAF-12-24-G, & LAD-RAF-12-24-G-EZ

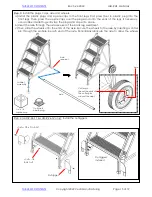

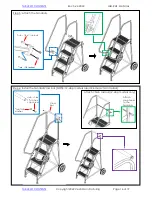

ASSEMBLY INSTRUCTIONS

Read the entire instruction manual before assembling this ladder. Improper assembly might

make the ladder unsafe to use.

•

Visually inspect the ladder components

prior to assembly

. Look at each part of the ladder immediately

after you receive the package from the shipper. Look for damage that might have occurred during

shipping. DO NOT assemble or use the ladder stand if you notice any damage to one or more of the steps

or to any other structural element (step weldment, back leg weldment, base supports, and handrails) of the

ladder. Using the ladder stand despite weakness of a frame member could result in serious personal injuries.

DO NOT use your ladder stand if any of the hardware (bolts, nuts, etc.) is damaged. Contact Vestil to order

replacement parts.

•

DO NOT assemble the ladder by yourself. At least 2 people are needed for assembly.

•

Read the entire instruction manual before assembling this ladder.

•

DO NOT use the ladder if a wheel is damaged. Damaged wheels might cause the ladder to wobble and

tip when used.

•

ALWAYS use proper lifting techniques to minimize back strain if you must pick up ladder parts or move the

ladder.

The following tools are necessary to assemble the ladder:

1.

2 crescent wrenches (1/2in. or adjustable to 1/2in.)

2.

Rubber mallet

3.

Pliers, preferably needle nose, to bend arms of cotter pins

4.

Proper work clothing, eye protection, gloves

5.

Sturdy wall no shorter than 8 feet high

6.

At least 30ft by 10ft of floor space is required to raise or collapse the ladder

7.

(If indoors) ceiling at least 16ft high.

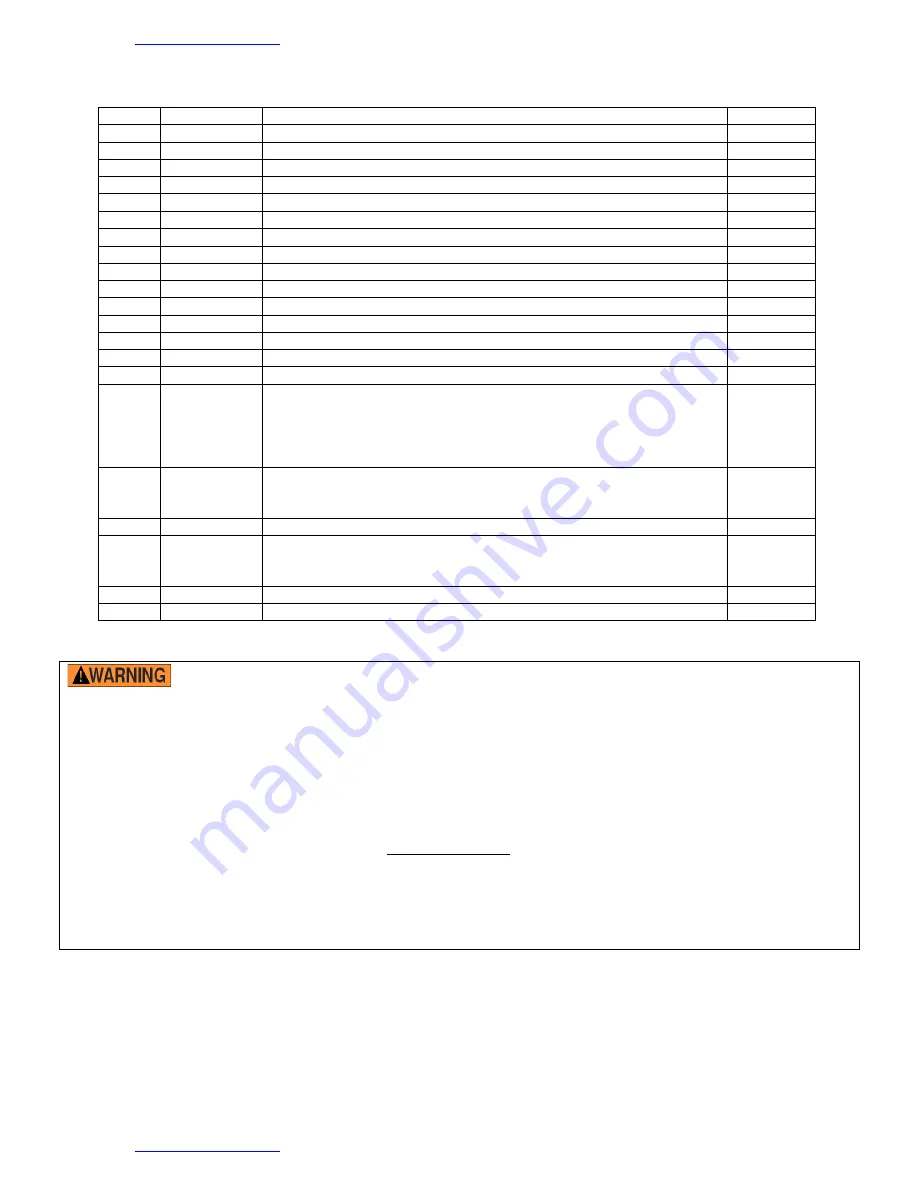

Item

Part no.

Description

Quantity

1

11059

5

/

16

in. – 18 UNC x 1

1

/

2

in. #2 zinc-plated bolt

18

2

37021

5

/

16

in. – 18 #2 zinc-plated nylon lock nut

22

3

11055

5

/

16

in. – 18 x 1 in. HHCS #2 zinc-plated bolt

2

4

44-112-007 Wheel axle

1

5

16-132-310 10 in. x 2

1

/

2

in., 16mm steel hub wheel

2

6

65125

2

/

16

in. x 1

1

/

2

in. zinc-plated cotter pin

2

7

99-024-027 1 in. x 1 in., 60 Duro. square cap

2

8

99-025-025 1 in. plastic plug

2

9

44-514-314 Weldment, frame, back platform

1

10

11053

5

/

16

in. – 18 x

3

/

4

in. HHCS #2 zinc-plated bolt

2

11

11108

3

/

8

in. – 16 x 1

3

/

8

in. zinc-plated hex cap screw

2

12

33008

3

/

8

in. USS zinc-plated flat washer

2

13

99-051-005

1

/

2

in. x 8 in. hook-and-loop fastening strap

2

14

44-514-310 Assembly, outrigger, right

1

15

44-514-311 Assembly, outrigger, left

1

16

44-647-021

44-647-029

44-647-037

44-647-0

Weldment, 12-step frame:

LAD-RAF-12-24-P

LAD-RAF-12-24-G

LAD-RAF-12-24-P-EZ

LAD-RAF-12-24-G-EZ

1

1

1

1

17

44-524-048

44-524-054

Weldment, handrail:

LAD-RF-12-24-P & LAD-RF-12-24-G

LAD-RF-12-24-P-EZ & LAD-RF-12-24-G-EZ

2

2

18

44-514-323 Weldment, back leg

1

19

44-014-403

44-014-516

Base support:

LAD-RF-12-24-P & LAD-RF-12-24-G

LAD-RF-12-24-P-EZ & LAD-RF-12-24-G-EZ

2

2

20

99-145-031

3

/

16

in. chain 24 in. long

1

21

08-145-008

1

/

4

in. snap hook

2