Rev. 5.24.2022

LAD-RAF, MANUAL

Copyright 2022 Vestil Manufacturing

Page 18 of 19

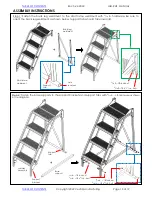

cross bar and the chain and snap hooks (if included with your ladder model). Confirm that the cross bar

and chain are undamaged and securely fastened to the guard railing. Snap hooks should close

automatically.

•

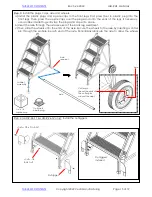

Axle, axle receiver/back leg weldment and wheels

: Make sure that the back leg weldment is

undamaged, e.g. not bent, cracked, or warped. Check the wheels. They must not be cracked or

significantly worn. Wheels should be vertical (not angled towards or away from the ladder) and should roll

smoothly. Make sure that the axle and the axle receiver are undamaged. The wheel retaining cotter pins

must be securely fastened to the axle.

•

All frame members (step weldment, back leg weldment, base supports, handrails) and all fasteners (bolts,

nuts, pins)

: Inspect each frame member weekly for damage like excessive wear, warps, cracks, and other

types of damage. All frame pieces should be square, rigid, and free of rust and corrosion. Remove rust

with steel wool or a metal bristle brush and apply touch-up paint to the affected area. Check the areas

where frame members are bolted together. Check the areas around bolt holes for warps, cracks, etc.

Replace all parts that are damaged before using the ladder again.

•

Square (rubber) caps

: Check the caps for cracks, tears, and wear. Install replacement caps before

returning the ladder to service. Even a moderate amount of wear can affect the ability of a cap to resist

sliding movement.

•

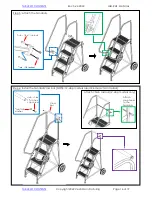

Outriggers (11 and 12 step models)

: Examine the outriggers and confirm that they are securely fastened

to the step weldment. Both outriggers should make solid contact with the ground, i.e. the ladder should

not be able to wobble. Confirm that the caps on the outrigger legs are in satisfactory condition.

Maintenance

: in addition to correcting issues discovered during inspections, maintain the ladder

as described below.

•

Clean the ladder to remove dirt and grime, especially from step surfaces.

•

Lubricate the axle as necessary for the wheels to rotate freely.

•

Apply touchup paint wherever the finish is chipped.

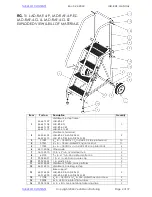

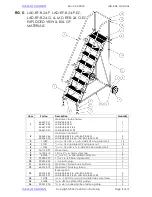

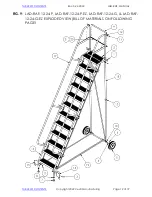

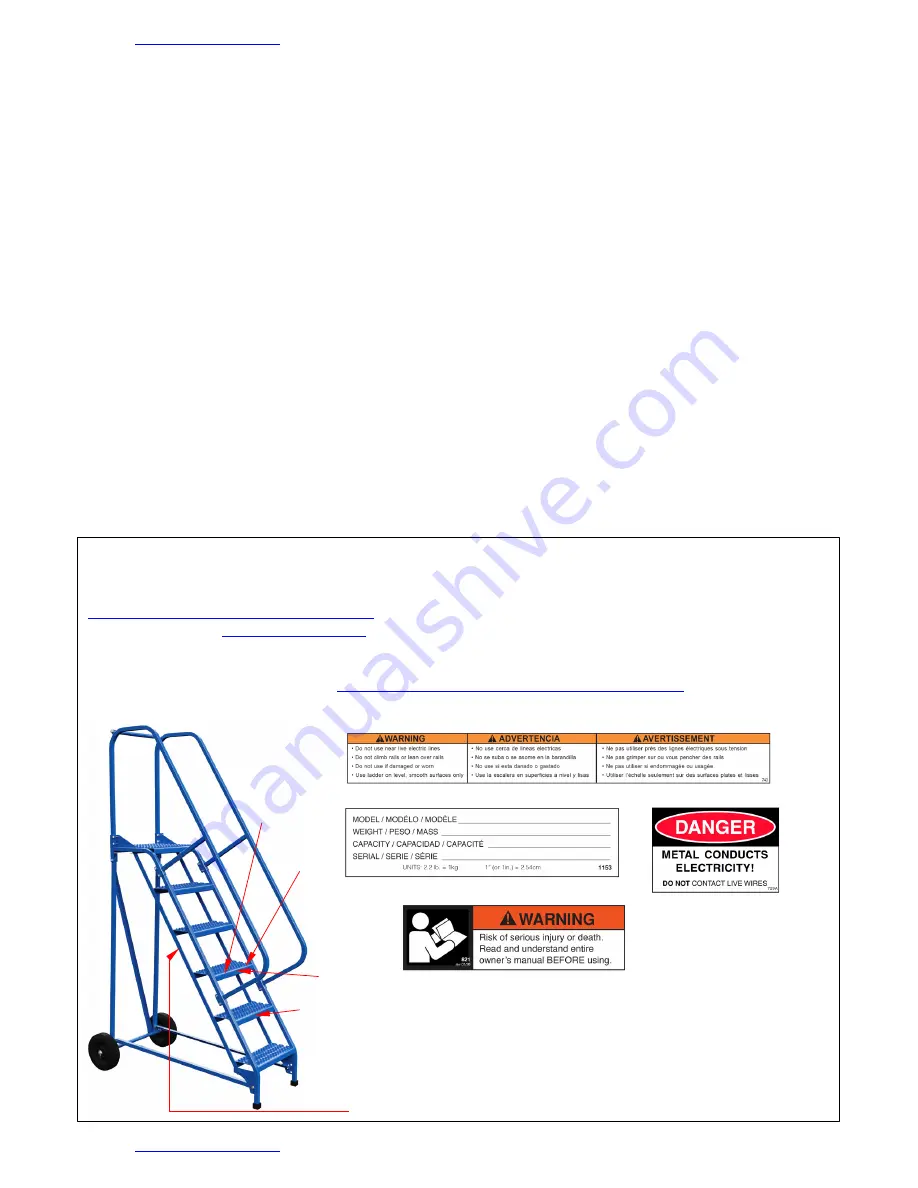

LABELING DIAGRAM

Each unit should be labeled as shown in the diagram. Label content and location are subject to

change so your product might not be labeled exactly as shown. Compare the diagram below to your

RECORD OF SATISFACTORY CONDITION

. If there are any differences between actual labeling and this

Replace all labels that are damaged, missing, or not easily readable (e.g. faded). To order

replacement labels or to inquire whether your unit is properly labeled, contact the technical service

and parts department online at

https://www.vestil.com/page-parts-request.php

665-7586 and asking for the Parts Department.

B

: Label 1153

C

: Label 729A

A

: Label 740

D

: Label 821

A

B

C

D

NOTE:

To provide access to this manual for all persons who use

this ladder, a protected copy of the manual should be attached

to the ladder. For example, a copy of the manual can be

placed inside a transparent plastic pouch or folder that is tied to

the ladder frame. An appropriate place to tie the folder to the

frame is on the side rail next to the step where label 821 is

applied.