Rev. 7/14/2021

LLCB-202058 MANUAL

Copyright 2021 Vestil Manufacturing Co.

Page

2

of

8

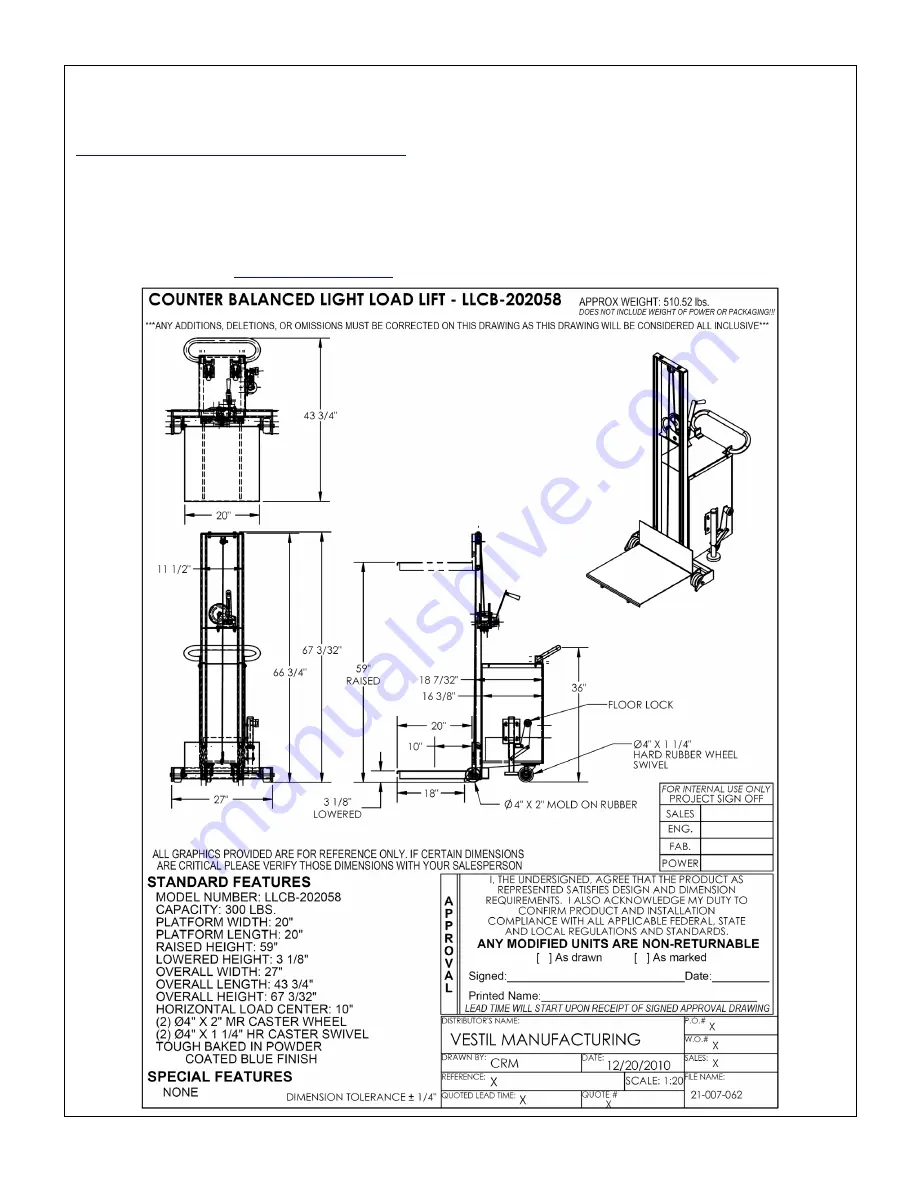

SPECIFICATIONS (21-006-062)

Specifications for LLCB-202058 counterbalanced light lifts are provided on Vestil’s website. To

access the appropriate specifications document, navigate to this webpage:

https://www.vestil.com/product.php?FID=263

Click the “Product Specifications Table” tab. Scroll

the page to the table row for model LLCB-202058 and click the button in the PDF column that

looks like a pencil inside a box. A PDF document will open. This file is the specifications

document. Print a copy of the document and keep it with your copy of this manual. The

following is an exemplar copy of the specifications document that is current as of the

publication date of this manual. If you have any questions about the specifications document,

please contact the