Rev. 7/14/2021

LLCB-202058 MANUAL

Copyright 2021 Vestil Manufacturing Co.

Page

5

of

8

NATIONAL STANDARDS

This product is a manually propelled high lift truck. The Industrial Truck Standards Development

Foundation (ITSDF) publishes national standard ANSI/ITSDF B56.10 (the “Standard”) on its website

). The standard is freely downloadable at

http://www.itsdf.org/cue/b56-standards.html

Before putting the unit into service, acquire a copy of the Standard and apply all recommendations in Part

II: For the User. If instructions provided in this manual conflict with instructions in the Standard, then you

should apply the instructions in the Standard. Vestil encourages you to immediately contact

TECHNICAL

SERVICE

to report any differences between instructions in this manual and the Standard.

USING THE LIFTER

This product is a manually-propelled high lift truck of the sort describes in American national standard

ANSI/ITSDF B56.10 (“B56.10” or the “Standard”). Vestil recommends that the owner of this product acquire a

copy of the latest revision of B56.10, which is available at no cost through the ITSDF website (

).

The copy, along with this manual, should be available to all persons who use this product. Instructions in this

manual are meant to

complement

the information provided in

Part II – For the User

of the Standard.

ONLY use this device after completing the operator training program in B56.10, sections 4.17 and 4.18.1-4.

•

Develop safe working habits and an awareness of hazardous conditions occurring or present during

operation of the lifter.

•

Inspect the area where the lifter will be used

before each use

to identify unusual operating conditions.

Implement additional safety precautions as conditions require. Conditions might include:

1. Irregularities in the floor/surface.

2. Debris or other obstructions on the floor/surface.

3. Unsound surfaces or surfaces that cannot support your weight plus the weight of the lifter and a full

capacity load.

•

Perform the following

function test before each use

:

1. Raise and lower the platform and confirm normal operating condition of the lift mechanisms.

2. Test the casters/wheels: wheels should roll smoothly, should not be severely worn, and should be

rigidly fastened to the frame of the lifter.

Use the lifter only if it is in

, p. 7.

Step 1

: Grasp the handle with both hands. Walk behind the lifter and keep your feet away from the

wheels. ONLY use the lifter on even, level, concrete surfaces.

Step 2

: Move the lifter to load.

Apply the floor lock by firmly

pressing down on the lock lever.

Confirm that the foot pad of the

floor lock solidly contacts the floor

by trying to push the lifter. The

lifter should

resist

forward/backward movement

while the lock is applied. The floor

lock will not

prevent

movement.

Press lock lever down to

engage floor lock

Lift to vertical position

(shown) to disengage

floor lock

Foot pad of floor lock

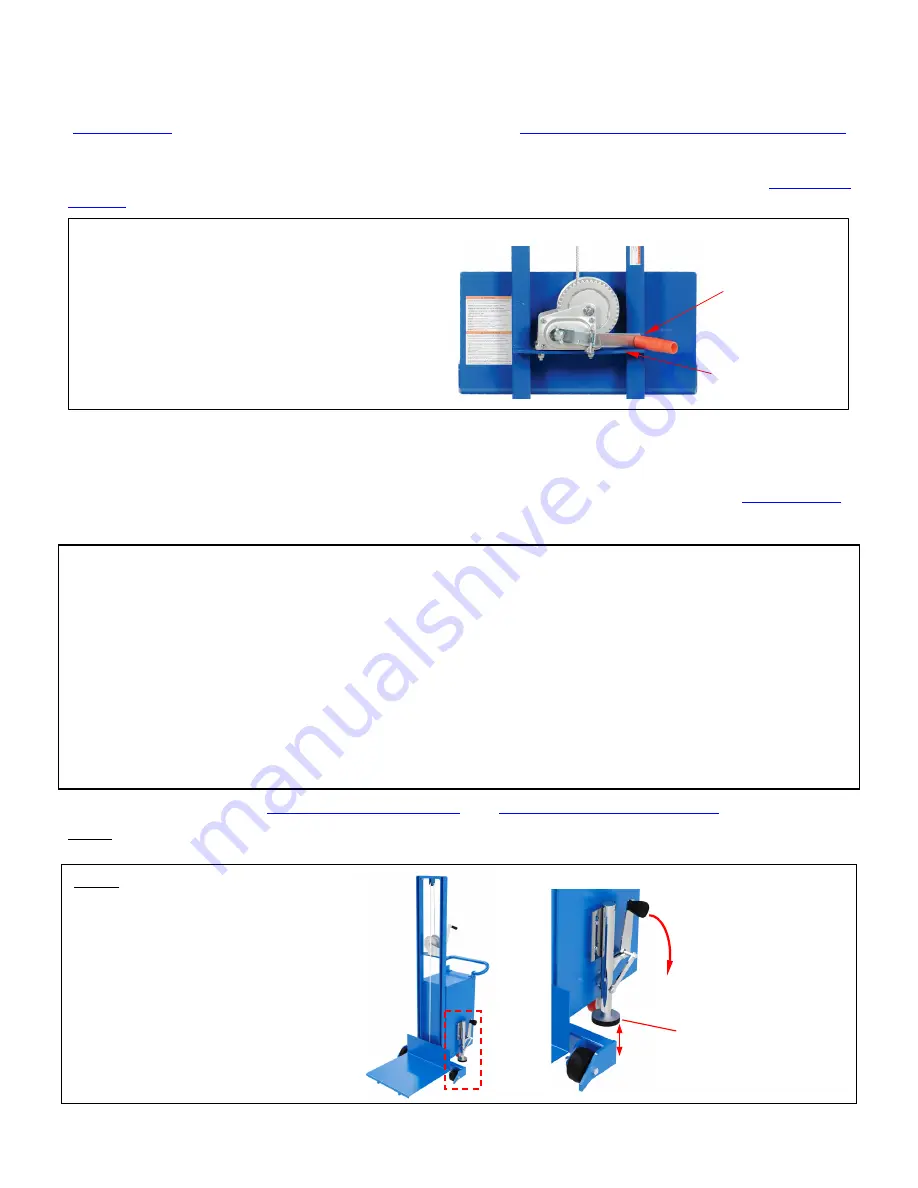

RAISING AND LOWERING THE PLATFORM

To raise and lower the platform, the lifter is

equipped with a manual winch. Raise the

platform by rotating the handle clockwise. The

platform rises ~1 inch with each rotation. Lower

the platform

by

turning

the handle

counterclockwise. Lay the handle on the winch

mounting bracket as shown when the platform is

elevated.

Rest winch handle

on winch mounting

bracket whenever

platform elevated

Winch mounting

bracket