6/10/2021

LM-HP MANUAL

Vestil Manufacturing

Page

4

of

6

INSTALLING & USING THE ATTACHMENT

This product is a fork attachment subject to Federal OSHA Rule

The Rule states that you must request that either the manufacturer of your fork truck, or a

professional engineer, determine how using the lifter attachment will affect the capacity,

operation, and maintenance of your fork truck. Truck data plates, tags, labels, etc. must be

changed accordingly. The truck should also be marked to identify the attachment and to

display the approximate weight of the truck and attachment combination at maximum

elevation with load laterally centered.

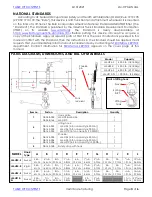

Installation

1)

Adjust the positions of the forks on the fork carriage to align with the fork receivers; then slide

the unit onto the forks. Keep the forks level.

2)

Attach the safety strap to the fork carriage of your lift truck. Wrap the safety strap around the

fork carriage. Attach the hook (at the free end of the strap) to the safety strap. The strap must

be wrapped around the carriage a sufficient number of times so that there is no slack in the

strap. The strap must prevent the unit from sliding forward on the forks.

Using the Device

Adjust the position of the fork truck to vertically and horizontally align the lifting hook with

the center of gravity of the load. Connect the load to the hook via appropriate rigging. The

weight of the load must not exceed the capacity of the hook. [NOTE: Capacity appears on

the surface of the hook. It is also displayed on tag 1054. See

Connect the load to the hook to minimize load swing when the load is lifted off of the ground.

Swinging loads might cause injuries and/or could damage equipment.

RECORD OF SATISFACTORY CONDITION

Before putting the unit into service, make a record of its condition. Photograph both sides of

the device. Take close range photos of the hook, shackle, safety strap, and strap hook.

Photograph both sides of tag 1054. See

openings of both hooks. Collate the photos and written descriptions into a single file. This file is

a record of the product in satisfactory condition. Compare the results of each inspection to

this RECORD to determine whether the unit is in satisfactory condition.

INSPECTIONS & MAINTENANCE

NOTICE

Proper use, maintenance, and storage are essential for this product to function properly.

o

Inspect the unit as instructed and as frequently as instructed.

o

Inspect and maintain the product as recommended in the current revision of ANSI/ITSDF

B56.1, as well as all instructions in this manual.

o

Store the unit in a dry location.

Compare the results of each inspection to the

RECORD OF SATISFACTORY CONDITION

to

determine whether the unit is in satisfactory condition. DO NOT use the lifter unless it is in

satisfactory condition. Only use manufacturer-approved replacement parts to restore the unit

to satisfactory condition.

Never make temporary repairs of damaged or missing parts

.

DON’T

GUESS!

If you have any questions about the condition of your lifter, contact the

TECHNICAL

SERVICE

department.

The phone number is provided on the cover page of this manual. Purely

cosmetic changes, such as chipped paint, are not changes from satisfactory condition.

However, touchup paint should be applied to all areas where the finish is damaged as soon as

the damage occurs. Exposed metal rusts. If left exposed, rust could compromise the soundness

of the metal and create a safety hazard.