Operation:

The speed control knob should already be in the “Stop” position, but if not, turn the knob to “Stop”.

Insert a key (two keys are enclosed inside packaging with this manual) into the slot in the key switch, and turn the key

to the “On” position. The battery charge/capacity display (see FIG. 6) will illuminate when system power is turned on

(see Fig. 6 on p. 3). The red LED will flash if the batteries require recharging.

Select the desired speed setting: low or high with the speed selection knob. To propel the cart, grasp the handle and

press the self-propulsion lever and handle together.

Slowly

and gradually release the lever to stop the cart.

Turn the speed selection knob to “Stop” before the cart is left unattended.

The “Direction governing lever” prevents accidental operation in reverse. To use the lever, pivot it over the operation

control panel as shown in FIG. 6. Always use the lever when operating the cart in forward (low or high). To operate

the cart in reverse, flip up the lever, turn the speed selection knob to “Reverse”, and then press the self-propulsion

lever and handle together.

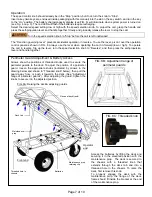

Perimeter Guard Adjustment & Battery Access

FIG. 8B: Adjustment range of

perimeter guards

Maintenance

prop

Arrows show the positions of threaded knobs used to secure the

perimeter guards to the deck. To adjust the position of a perimeter

guard, loosen the appropriate knobs (indicated by arrows in the

drawing below and shown in “Threaded knob” below); then pull the

guard away from, or push it towards, the deck (See “Adjustment

range of perimeter guards”). After adjusting the guard, tighten the

knobs to secure it in the adjusted position.

FIG. 8A: Raising the deck & adjusting guards

Threaded hole in

chassis

Deck tab

FIG. 8C: Threaded knob

Maintenance prop

retaining clip

Flange of deck fram

e

Operator

end

Front end

Access the batteries by lifting the deck and

securing it in the elevated position with the

maintenance prop. The deck is secured to

the chassis with a threaded knob that

extends through the deck tab and into a

threaded hole in the chassis. To raise the

deck, first remove this knob.

To properly engage the deck with the

maintenance prop, the flange of the deck

frame should fit inside the bracket at the end

of the maintenance prop.

Batteries

Page 7 of 10

Summary of Contents for OROAD-400

Page 5: ......