Rev. 7/16/2021

SPS3 MANUAL

COPYRIGHT 2021 VESTIL MANUFACTURING CO. PAGE 6 OF 7

INSPECTIONS & MAINTENANCE

NOTICE

Use and store the cart indoors where it will remain dry. Inspect and maintain the cart as

instructed to maximize the usable life of the cart. Inspections and all necessary repairs should be

performed by qualified persons.

Compare the results of each inspection to the

RECORD

OF SATISFACTORY CONDITION

. Do not

use the cart unless every part is in satisfactory condition. If you have any questions about the

condition of your cart, contact the

TECHNICAL SERVICE

department. The phone number is

provided on the cover page of this manual.

Never make temporary repairs of damaged or

missing parts

. Only use manufacturer-approved replacement parts to restore the unit to

satisfactory condition.

I

nspect the following at least once per month. Maintain the cart by replacing all items that are

not in satisfactory condition.

1)

Frame and shelves – Look for damage and deformation, severe corrosion, etc. Check all

welds for cracks. Push the unloaded cart and listen for unusual noises and movement. Clean

the shelves and steps. Absorb water and other liquids.

2)

Step assembly – Confirm that the steps and springs operate normally. All 4 rubber feet must be

in place, undamaged, and not significantly worn. The feet have washers inside their cavities to

prevent the handles from tearing through the material. Confirm that such tearing has not

occurred. The rubber feet applied to the bottom ends of the handles should firmly contact the

ground when weight is applied to a step. The step assembly should slide up-and-down easily

when weight is applied to it.

3)

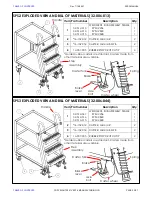

Casters – Examine the wheels, caster forks, axle bolts, brakes, and brake levers. See

EXPLODED

VIEWS

on p. 3. Apply the brakes. Confirm that brakes firmly contact their wheels. Try to push

and pull the cart.

4)

Hardware – Check all caster hardware/fasteners and spring pins. Tighten all loose fasteners.

5)

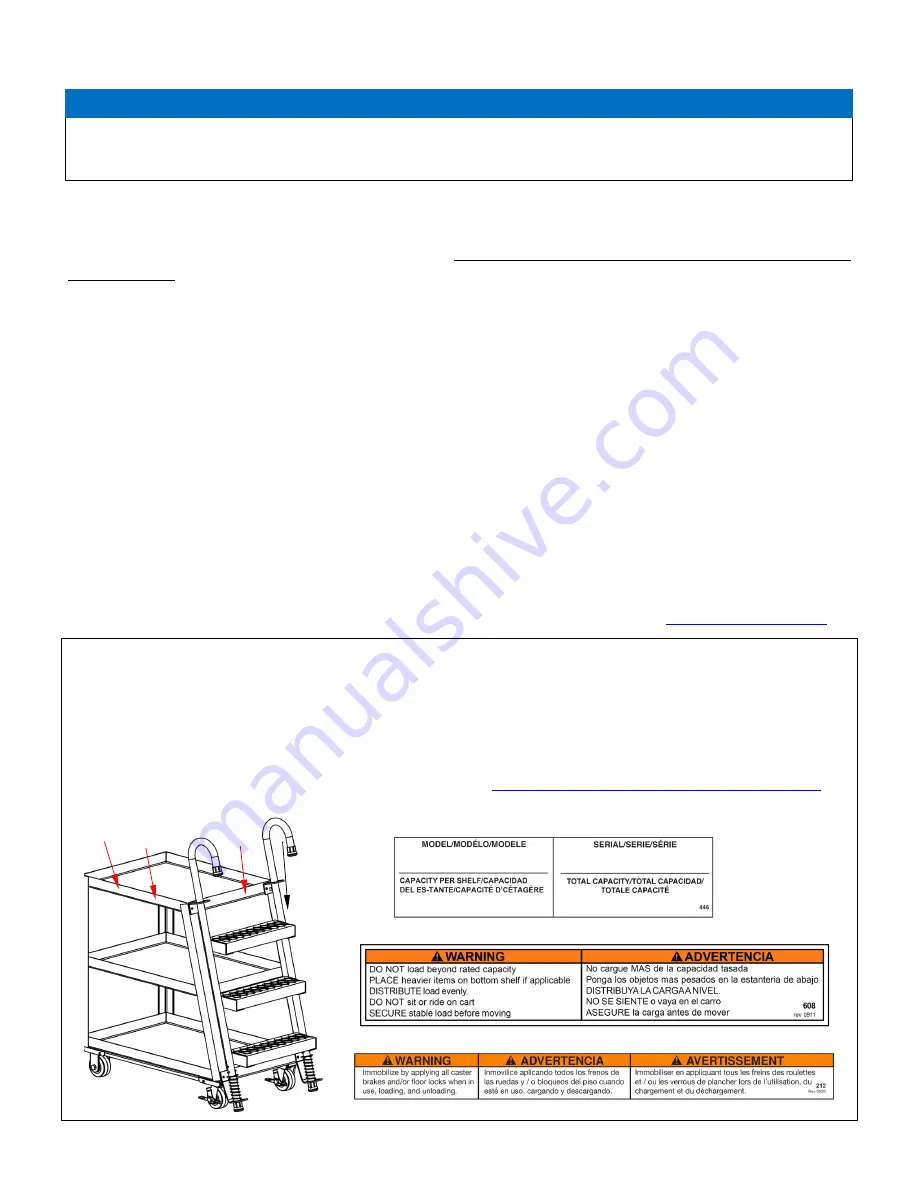

Labels – Confirm that each label is in place and in good condition. See

LABELING DIAGRAM

Label content and location are subject to change so your product might not be labeled

exactly as shown. Compare the diagram below to your

RECORD OF SATISFACTORY CONDITION

If there are any differences between actual labeling and this diagram, contact

TECHNICAL

SERVICE

. Replace all labels that are damaged, missing, or not easily readable (e.g. faded). To

order replacement labels or to inquire whether your unit is properly labeled, contact the

technical service and parts department online at

http://www.vestilmfg.com/parts_info.htm

by calling (260) 665-7586 and asking for the Parts Department.

A

:

Label 446

A

B

:

Label 608

B

C

C

:

Label 212