Vetrano Espresso Machine

16

Gasket and Screen Removal - Continued

Method 2

If the gasket and screen will not come out using

the previous method then you will need a scratch

awl or ice pick to remove them.

Using the scratch awl or ice pick, deeply pierce

the gasket and then pry it down. If the gasket is

old and dried out then it will be more difficult to

remove and will come out in pieces. Repeat until

all remnants of the old gasket are removed.

Cleaning The Group

Before installing the new gasket and screen it is very important to clean the group head.

Make up a solution of hot water and backflushing cleanser. Using the provided cleaning

brush and cleanser, clean the group head and be sure the groove that the gasket sits in

is completely free of any residual gasket material and coffee grounds or the new gasket

will not seat properly.

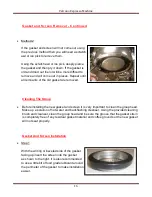

Gasket And Screen Installation

Step 1

With the writing or beveled side of the gasket

facing up insert the screen into the gasket

as shown to the right. It is also recommended

to use a little bit of food grade lubricant around

the perimeter of the gasket to make installation

easier.