4

Assembly

Check the compatibility prior to the installation.

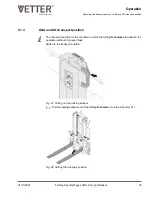

Folding

fork arms

, carrier vehicles, and fork carriers must always be compatible with

each other.

Danger to life from the use of incorrect components!

– Ensure that the folding fork arms used have the exact lifting dimensions of

the fork carrier.

– Ensure that the fork arms used have at least the load capacity of the fork car-

rier. Check the load chart of the carrier vehicle with regard to the transport

task.

– Compare the weight and the load center of the transport task with the infor-

mation on the type plate of the folding fork arms (

– Ensure that all safeguarding devices (fork arm locking device, locking

bracket) are fully in place as genuine components and are functioning flaw-

lessly.

If the system components are not compatible with each other (suspension type,

fork carrier, and fork arm), the safe transmission of power is not ensured and

there is a danger of serious accidents, e.g., due to breakage or the load falling.

The type of fork arm suspension may deviate from the image depending on the carrier

vehicle. Observe the operating manual for the carrier vehicle. DuoLoc (KGA-SBO),

KGA, and KGI are installed on the fork carrier using the same locking device

Chapter 3.4 “Locking device” on page 23).

Risk of injury from crushing!

– Wear protective gloves.

– Exercise caution and act with reason when sliding the folding fork arms up

and down.

– Do not open and close the locking mechanisms by force.

Due to the high weight of the folding fork arms, crushing can result in serious

injuries. This must be observed during all assembly, disassembly, and adjust-

ment tasks.

Personnel:

n

Driver of carrier vehicles

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

NOTICE

Incompatibility

L

WARNING

Crushing

L

WARNING

Assembly

V1.07/2021

Folding fork armsTypes KGA, KGI, and DuoLoc

24