6

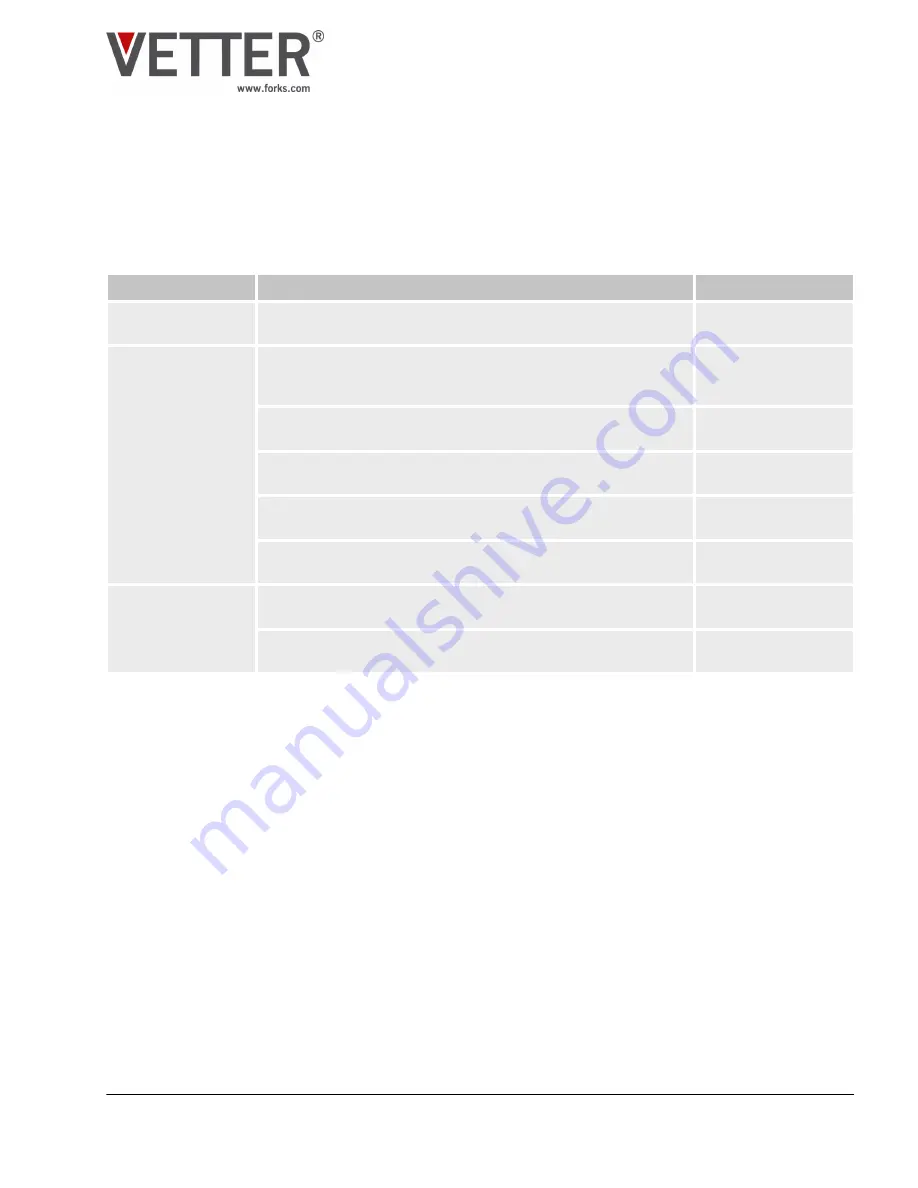

Maintenance

6.1

Maintenance intervals

Interval

Maintenance work

Personnel

Daily

Visual inspection performed by the driver

“Daily visual inspection by the driver” on page 39

Driver of carrier vehi-

cles

At least once annu-

ally*

Performing regular fork arm inspection including accident pre-

vention inspection in accordance with ANSI/ITSDF B56.1

Chapter 6.2.2 “Fork arm inspection ” on page 41

Service specialist

Performing a check for wear in accordance with ANSI/ITSDF

B56.1

Chapter 6.2.3 “Check for wear” on page 41

Service specialist

Checking the locking device

Service specialist

Checking the locking bracket

Service specialist

Checking the suspension

Chapter 6.2.6 “Checking the sus-

Service specialist

If necessary

Replacing the fork arm

Chapter 6.2.8 “Replacing the fork

Driver of carrier vehi-

cles

Chapter 6.2.7 “Cleaning the fork arm” on page 45

Driver of carrier vehi-

cles

* Depending on operating time, wear and use, the operator can choose a much shorter

interval at their own responsibility.

6.2

Maintenance activities

6.2.1

Daily visual inspection by the driver

Personnel:

n

Driver of carrier vehicles

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Maintenance

Maintenance activities > Daily visual inspection by the driver

V1.07/2021

Folding fork armsTypes KGA, KGI, and DuoLoc

39