4

Assembly and disassembly

4.1

Assembly

NOTICE!

Carry out a compatibility check prior to assembly.

1.

Compare the suspension dimensions of the fork carriage with those of the

Manu

Tel

®

G2.

2.

Compare the load chart of the industrial truck with the Manu

Tel

®

G2:

n

Determine the weight and load centre for the transport task.

n

Check the load chart of the industrial truck with regard to the transport task.

n

Check the load chart of the Manu

Tel

®

G2 with regard to the transport task.

3.

In the event of compatibility, carry out assembly.

The type of fork arm suspension may deviate from the image depending

on the industrial truck. Observe the operating manual for the industrial

truck.

WARNING!

Risk of injury from crushing!

Due to the considerable weight of the fork arms, crushing can result in

serious injuries. Note the following points in relation to all of the following

assembly, disassembly and adjustment tasks:

–

Wear protective gloves.

–

Carry out lifting and lowering of fork arms with care and prudence.

–

Do not use force to open and close locking latches.

Personnel:

n

Driver of industrial trucks

Protective equipment:

n

Industrial helmet

n

Protective work clothing

n

Protective gloves

n

Safety shoes

Special tool:

n

Lifting device

Carry out assembly of the Manu

Tel

®

G2 on the fork carriage in the following order:

1.

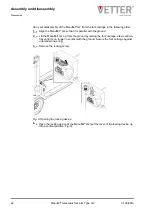

Prepare the lifting device for large loads, e.g. indoor crane and lifting straps. The

work is to be carried out by 2 people.

2.

Move the fork carriage to the vertical position and move it to a height that allows for

safe and comfortable installation of the Manu

Tel

®

G2.

3.

Remove the locking screw on the assembly side of the fork carriage.

Checking

compatibility

Assembly

Assembly and disassembly

Assembly

V1.09/2019

ManuTel

®

telescopic fork arm Type G2

19