5

Operation

5.1

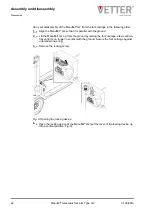

Telescoping the ManuTel

®

G2

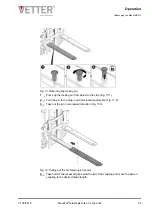

The slip-on coupling is secured by connecting the borehole in the fork carriage to a

locking pin.

WARNING!

Insufficient lock!

If the lock for the slip-on coupling and basic fork arm is insufficient, this

can lead to loads being transported in an unsafe manner. There is a risk

of injury from the load slipping.

–

The locking pin must always be completely countersunk in the basic

fork arm.

–

Working without a locked slip-on coupling is not permissible.

DANGER!

Risk of injury from shearing forces!

Considerable shearing forces can result from the unsecured movement of

the slip-on coupling on the basic fork arm. Fingers and body parts located

in the opening of the basic fork arm and slip-on coupling could be seri-

ously injured or even severed!

–

Never put fingers or any other body parts into the openings of the

basic fork arm and slip-on coupling.

–

Always secure the connection between the basic fork arm and slip-on

coupling with the locking pin intended to serve this purpose.

–

Only use the intended locking pin. Never use makeshift solutions

(e.g. screws).

–

Wear protective gloves.

Personnel:

n

Driver of industrial trucks

Protective equipment:

n

Protective work clothing

n

Industrial helmet

n

Protective gloves

n

Safety shoes

Operation

Telescoping the ManuTel® G2

V1.09/2019

ManuTel

®

telescopic fork arm Type G2

24