4.3

Fork arms with shaft suspension

Personnel:

n

Driver of carrier vehicles

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Disassembly

Proper disassembly is described under

Chapter 6.6 “Replacing the fork arms”

Shaft fork arm locking device

Depending on the operator's requirements and intended use, shaft fork arms are sup-

plied as follows: either freely movable on the shaft, using adjusting rings on both sides

of the two shaft fork arms, or with a locking screw on the shaft.

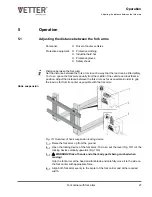

Assemble the fork arms on the fork carrier in the following order:

1.

Prepare the lifting device for large loads, e.g., indoor crane and lifting straps. The

work must be carried out by 2 people.

2.

Move the fork carrier to the vertical position and move it to a height that allows for

safe and comfortable assembly of the fork arm.

3.

Remove the safeguarding device from one side of the shaft.

4.

Pull the shaft out to the side and put it aside safely.

5.

Secure the fork arm with the lifting device (e.g., using a crane and belts). Lift and

position it in such a way that the boreholes of the sockets are level with the elon-

gated holes of the fork carrier.

Assembly

Assembly

Fork arms with shaft suspension

Fork carrier with fork arms

25

Summary of Contents for ManuTel

Page 2: ...Fork carrier with fork arms 2 ...

Page 52: ......