Danger to life due to unsecured vehicle or moving parts!

Always note the following prior to any maintenance measure:

– Secure the carrier vehicle to prevent it from rolling away inadvertently.

– Always use a suitable lifting device for heavy parts.

– During the disassembly of fork carriers and fork arms, ensure that loosened

parts do not fall down or tip over.

– Immediately place disassembled components to one side to prevent them

falling.

Uncontrolled movements of the vehicle or parts can result in serious injuries or

even death due to the high dead weight.

n

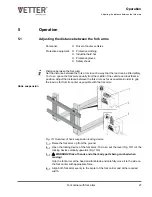

Check the locking device of the hook-on fork arm for functionality:

– Ensure that the hook-on fork arm is engaged in the correct locking groove

– Ensure that the hook-on fork arm lever is fully engaged.

n

Function check for the locking screw:

– Ensure that the hook-on fork arm cannot be pushed off of the fork carrier from the

side when the fork arm locking device is open or loosened.

n

Check the safeguarding device and adjusting rings of the shaft suspension:

– Ensure that the safeguarding device, as well as the adjusting rings or locking

screw, are in place and securely mounted.

n

The fork arms must be free from dirt (including grease) and ice.

n

The fork arm hooks must not show any signs of damage.

n

The fork carrier and the fork arms must not have any deformations, cracks, damage,

or sharp edges.

n

The safety marking must be complete and legible. If the marking is illegible, immedi-

ately prevent further use of the fork arms.

n

Perform a visual inspection for wear on the fork bend and fork blade.

6.3

Checking the fork carrier

Personnel:

n

Service specialist

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Hazard prevention at

the workplace

L

WARNING

Maintenance

Checking the fork carrier

Fork carrier with fork arms

31

Summary of Contents for ManuTel

Page 2: ...Fork carrier with fork arms 2 ...

Page 52: ......