In addition, always observe the following:

–

Check the fork carrier for any permanent deformation at regular intervals. Immedi-

ately prevent further use of deformed fork carriers and have them checked by a

trained service specialist.

–

Check the fork carrier and fork arms for deformation and cracks using suitable pro-

cedures. Have such procedures performed by trained service specialists as part of

the legally prescribed inspection. Pay particular attention to the areas of the upper

suspension and to the welded connections. If there are any signs of cracks, immedi-

ately ban any further use of the fork carriers and fork arms.

The driver of the carrier vehicle is obligated to perform regular visual inspections of the

fork carrier.

6.4

Checking the fork arms

Risk of injury due to irregular checks!

– Have the fork arms checked by a service specialist or the manufacturer at

least once a year (more frequently for heavy usage or multiple-shift opera-

tion).

– Carry out the test based on the currently relevant standard. The service spe-

cialist will specify the scope of the test and the test interval.

The load capacity of the fork arms is impaired if the fork arms are damaged.

Using damaged forks (e.g., in the event of material breakage due to micro

cracks) can lead to serious accidents.

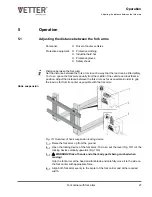

6.4.1

Checking the locking device and safeguarding device

Personnel:

n

Driver of carrier vehicles

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Incorrect checks

L

WARNING

Maintenance

Checking the fork arms > Checking the locking device and safeguarding device

Fork carrier with fork arms

32

Summary of Contents for ManuTel

Page 2: ...Fork carrier with fork arms 2 ...

Page 52: ......