3.2

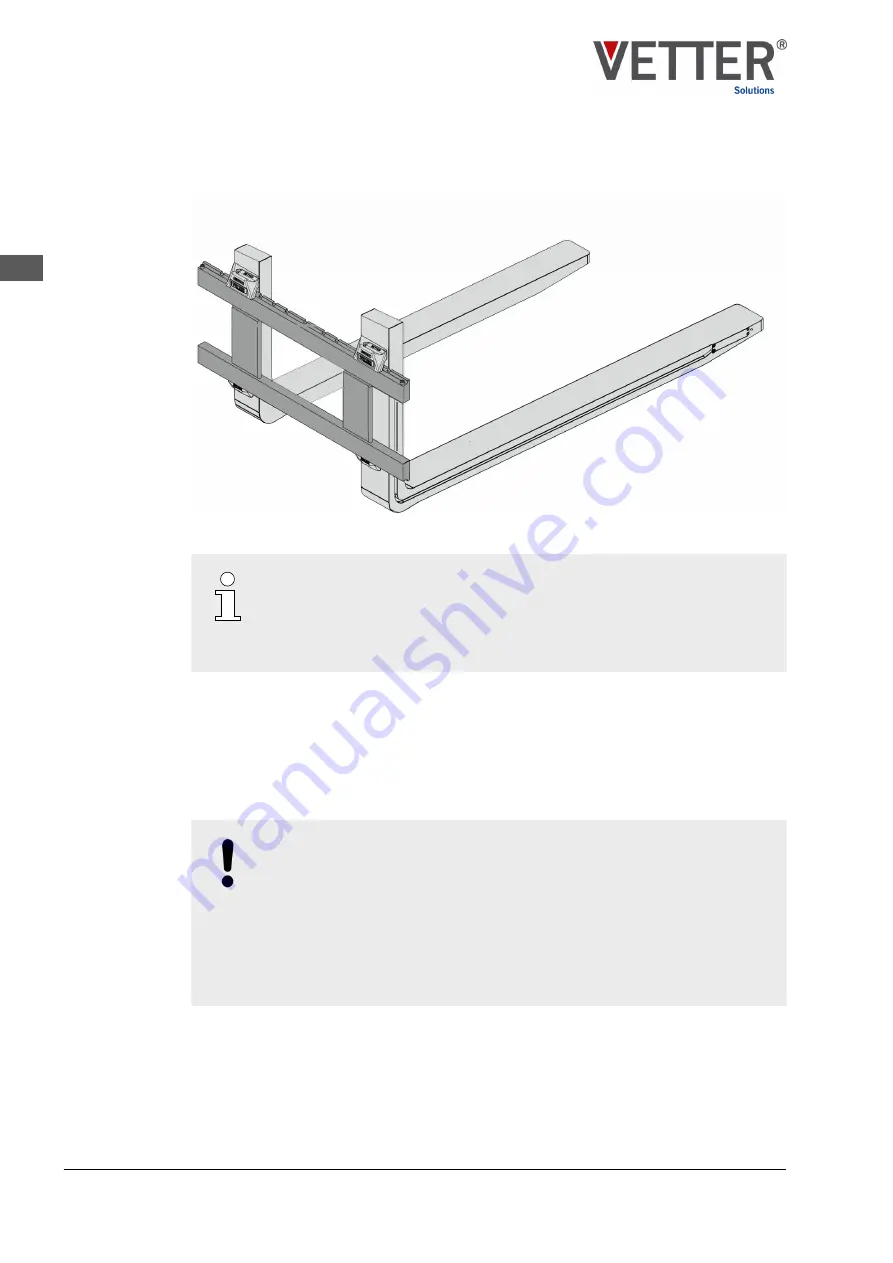

Suspension

Fig. 5: SmartFork

®

on the fork carrier

The type of fork arm suspension may deviate from the image depending

on the industrial truck. In addition to the hook suspension shown, other

suspension options are available, e.g. shaft suspension. For information

about assembly of this variant, please refer to the operating instruction for

the industrial truck and for the fork carrier used.

Assembly of the Smart

Fork

®

may only be carried out on a fork carrier that is compatible

with the Smart

Fork

®

supplied. In this context, compatible means that both hooks jointly

and securely encompass the fork carrier and, due to the design of the fork carrier profile,

a secure lock can be ensured by the locking device on the upper hook. Observe the rele-

vant operating instruction for the fork carrier installed on the industrial truck.

The attachment dimensions for the Smart

Fork

®

can be requested from customer service

) upon stating the order number (on the hard stamping).

NOTICE!

Providing equipotential bonding

Potential differences can result in dielectric breakdown and discharge as

short, high electric current. In this regard, there is a danger of flammable

substances being ignited in potentially explosive atmospheres.

– Following assembly of the fork arms on the industrial truck, ensure a

connection (contact) to the shared equipotential bonding of the indus-

“Establishing equipotential bonding” on page 32

Structure

Suspension

SmartFork

®

FrontCam ATEX for use in the Ex zone - BVS 20 ATEX E 108 X

28

EN