4.4

Connecting Drivers and Power Supplies

Use a power supply cable whose wire has a cross sectional area of at least 0.75

.

The power supply input current varies depending on the motor output (see tables below).

■

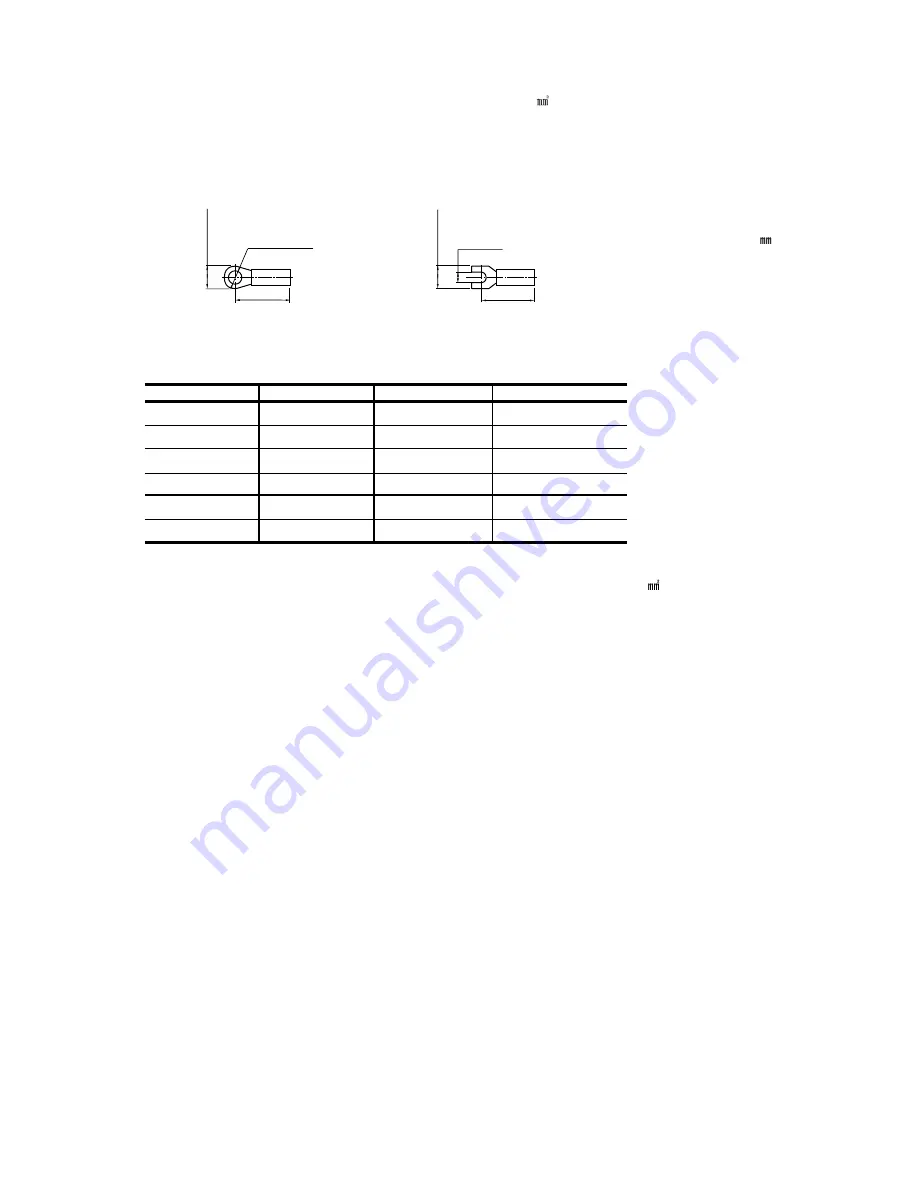

Recommended Terminal Rings

■

Power Supply Input Current

Note

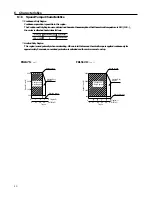

・The driver must be earthed with the earth wire of the protective earth terminal.

The earthing line must be as short as possible with using the wire type AWG #18 (0.75 ) or greater.

・

Once power has been turned off, do not turn power on again or remove or insert the motor connector for at least

1 minute.

12

φ

3.2MIN.

( .126DIA.MIN.)

9mmMIN.

( .35MIN.)

9mmMIN.

( .35MIN.)

・

Round shape terminal with insulation

・

U-shape terminal with insulation

3.2mmMIN.

( .126MIN.)

6.2mmMAX.

( .244MAX.)

6.2mmMAX.

( .244MAX.)

Combination Type

FBL575AW-

□

FBL5120AW-

□

FBL575CW-

□

FBL5120CW-

□

FBL575SW-

□

FBL5120SW-

□

Round Shaft Type

FBL575AW-A

FBL5120AW-A

FBL575CW-A

FBL5120CW-A

FBL575SW-A

FBL5120SW-A

Maximum Input Current

2.6A

3.8A

2.0A

2.7A

1.2A

1.6A

Pinion Shaft Type

FBL575AW-GFB

FBL5120AW-GFB

FBL575CW-GFB

FBL5120CW-GFB

FBL575SW-GFB

FBL5120SW-GFB

Note Keep the spacing between eath

terminals more than 6.4

,

when U-shape terminals are used.

4.5

Methods of Speed Setting and Their Connection

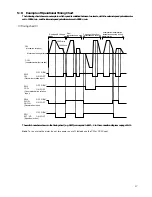

(1) The following three methods of setting speed can be used with

FBL

Ⅱ

units.

■

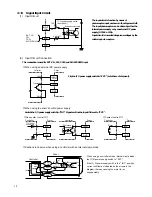

Internal Speed Potentiometer

Motor speed can be adjusted by turning the potentiometer screw on the driver's front panel. This method is suitable

for infrequent speed changes.

■

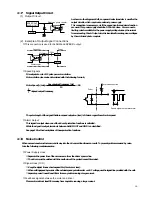

External Speed Potentiometer

Speed settings can be controlled remotely using the external speed potentiometer provided with the unit. This method is

suitable when adjusting speed from a control panel.

■

External DC Voltage

The motor speed can be changed with DC voltages of 0−5 V.

Have ready a DC power supply of 1 mA or more.

(2) Connection Methods

■

Internal Speed Potentiometer

The built-in speed potentiometer can be selected by turning off (i.e. switching to high) input to the EXT.VR. terminal ②.

The speed is set to 0 r/min when the product is shipped. Rotate clockwise to start the motor rotating.

Note Use a n insulated miniature screwdriver for adjusting the timing potentiometer.