4

1.3

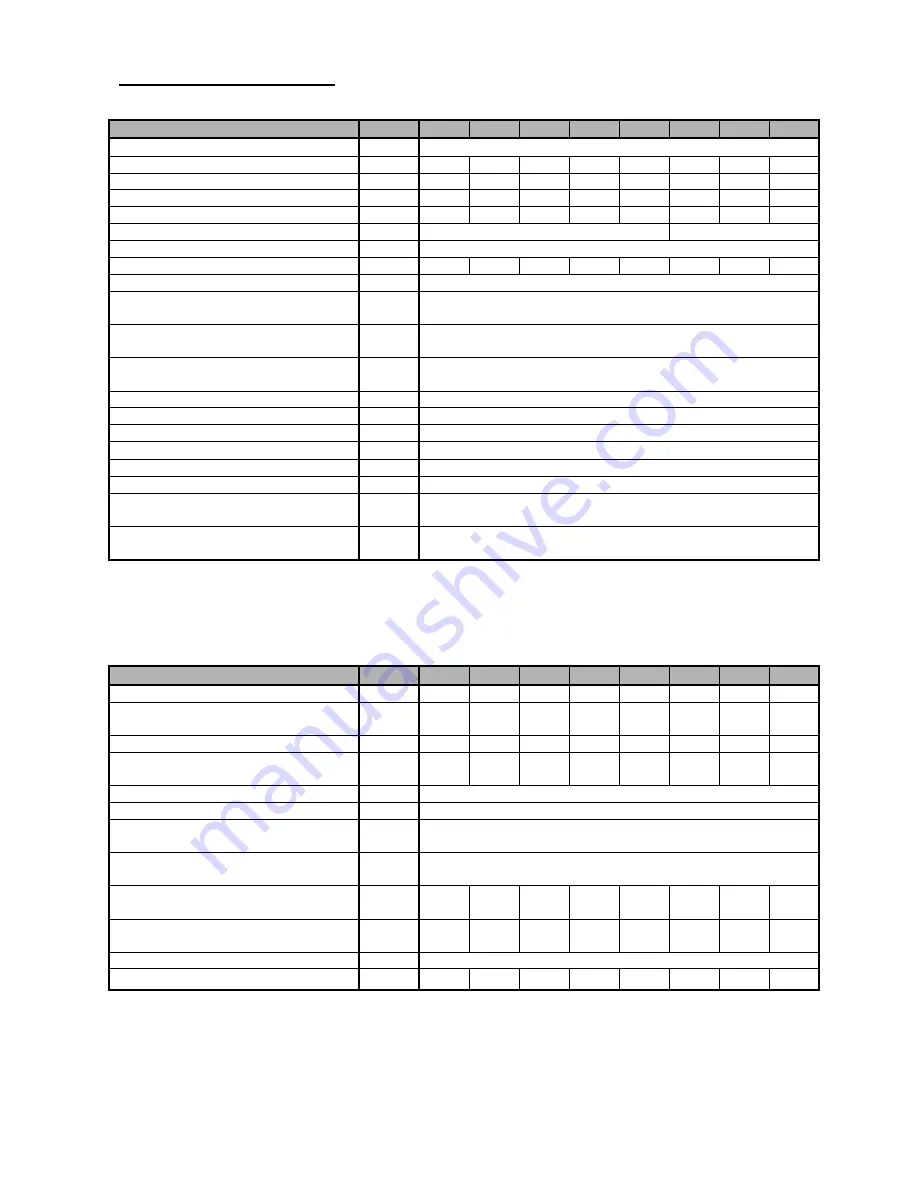

Boiler technical data

Tab. no. 1 Dimensions, technical data

Number of sections

pc

3

4

5

6

7

8

9

10

Boiler class according to EN 303 - 5

-

3

Combustion chamber volume

l

23,6

37,6

51,6

65,6

79,6

93,6

107,6 121,6

Water space volume

l

39,5

49,3

59,1

68,9

78,7

88,5

98

107,8

Weight

kg

262

312

362

412

462

512

562

612

Combustion chamber depth

mm

220

330

440

550

660

770

880

990

Diameter of smoke socket

mm

156

176

Boiler dimensions: height x width

mm

1161 x 665

depth L

mm

714

825

936

1047

1158

1269

1380

1491

Filling opening dimensions

mm

245x 195

Maximum working water overpressure

kPa

(bar)

400

(4)

Minimum working water overpressure

kPa

(bar)

50

(0,5)

Testing water overpressure

kPa

(bar)

800

(8)

Boiler hydraulic loss

-

See Fig. no. 1

Minimum output water temperature

°C

60

Control range of water temperature

°C

60 – 85

Noise level

dB

Does not exceed the level 65 dB (A)

Boiler connections – heating water

“

6/4

– return water

“

6/4

Cooling water temperature for

equipment for surplus heat withdaral

°C

5 – 20

Cooling water overpressure for

equipment for surplus heat withdaral

kPa

(bar)

200 – 600

(2-6)

Tab. no. 2 Technical data – hard coal as fuel

granularity 20 – 40 mm, fuel moisture max. 15 %

calorific value of fuel: 14 – 20 MJ.kg

-1

Number of sections

pc

3

4

5

6

7

8

9

10

Nominal heat output

kW

13

19

25

31

37

43

49

55

Fuel consumption at nominal heat

output

kg.h

-1

2,60

3,80

5,00

6,20

7,40

8,60

9,80

11,00

Minimum heat output

kW

3,9

5,7

7,5

9,3

11,1

12,9

14,7

16,5

Fuel consumption at minimum heat

output

kg.h

-1

0,79

1,15

1,51

1,87

2,23

2,60

2,96

3,32

Fuel efficiency

MJ.kg

-1

19,81

Burning time at nominal output

hour

4

Flue gases temperature at nominal

heat output

°C

220 – 250

Flue gases temperature at minimum

heat output

°C

110 – 120

Flue gases mass flow rate at nominal

output

g.s

-1

10,65 15,57 20,49 25,41 30,33 35,24 40,16 45,08

Flue gases mass flow rate at

minimum heat output

g.s

-1

4,92

7,19

9,46

11,73 14,00 16,27 18,54 20,81

Efficiency

%

78

Required chimney draught

mbar

0,13

0,14

0,15

0,20

0,22

0,28

0,30

0,32

Summary of Contents for Hercules U 24

Page 30: ...30 ...

Page 32: ...32 Updating date 6 2013 GB ...