9

4.2

Placement options

Placement of the boilers in living areas (including halls) is prohibited!

Steady supply of air for combustion and ventilation must be ensured to the room where the boiler is installed.

When installing and using the boiler, all requirements of CSN 06 1008 must be complied with.

Boilers in the central heating system have to be connected to a separate venting unit. The chimney with a correct draught is the basic

presumption for correct function of the boiler. It influence both the boiler power and its effectiveness. A flue-gas ducting from the

boiler to the venting unit has to be as short as possible, preferably without elbows with a slope from the boiler upwards. The chimney

has to have a prescribed draught (according to the boiler size – see the manual). It has to be well-tightened and insulated to avoid

condensation of water vapor and tar.

Placement of the boiler regarding the fire regulations:

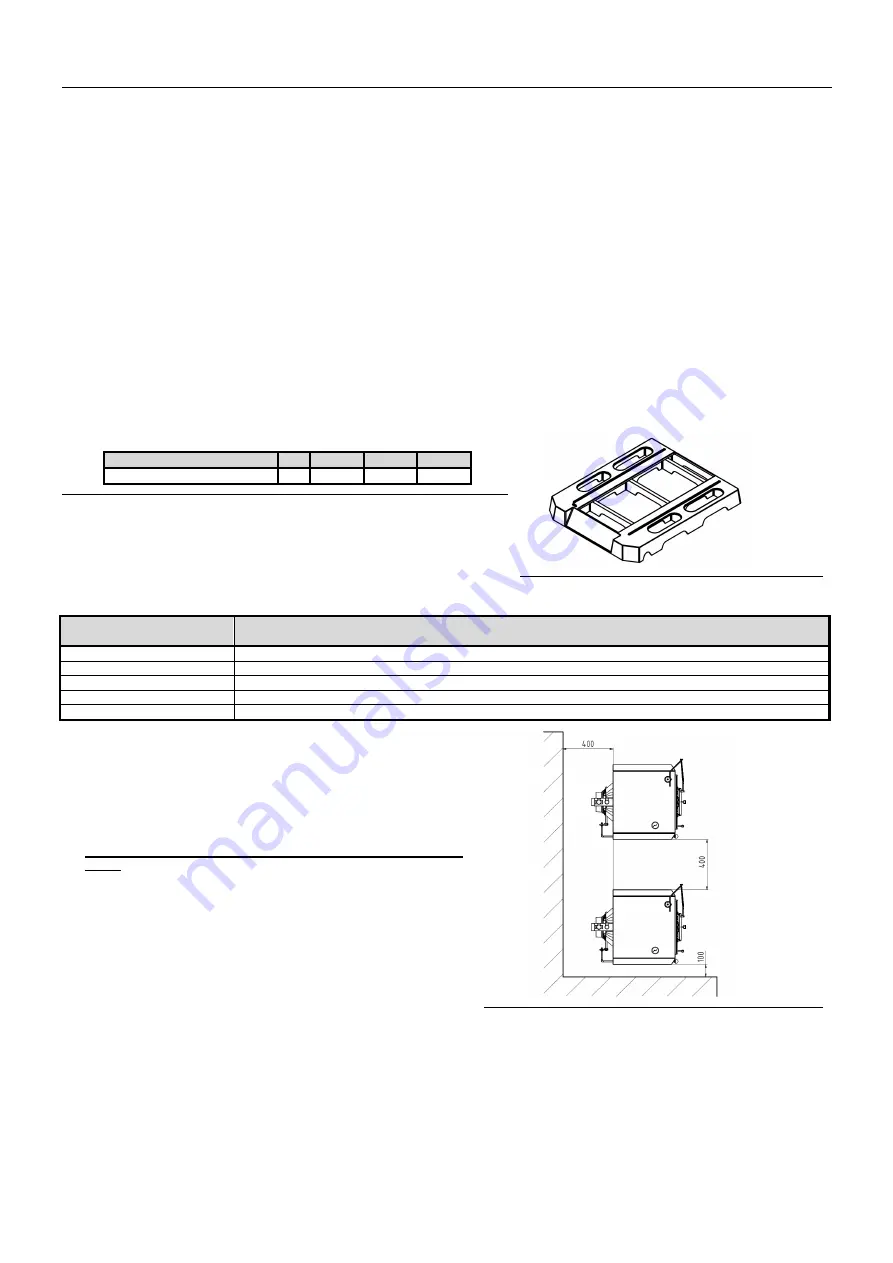

When installing the boiler, we recommend to use original cast iron basement (see Fig. 10) supplied by the manufacturer. When installing the

boiler without the basement, it is necessary to comply with the conditions set out in the point 1.

1. Placement on the floor made of incombustible material (Fig. 9):

−

place the boiler on a fireproof base exceeding the boiler dimensions only by the boiler drum depth and on the sides by 20 mm;

−

if the boiler is installed in a cellar, we recommend to install it on a substructure at least 50 mm high;

−

the boiler must be placed in the centre of the basement.

2. Safe distance from flammable materials

−

when installing and operating the boiler it is necessary to keep the safe distance of 200 mm from flammable materials with combustibility

grade A1, A2, B and C (D);

−

for easily flammable materials with combustibility grade E (F), which burn quickly and by themselves also after the ignition source

removal (e.g. paper, cardboard, asphalt and tar boards, wood and fibreboards, plastics, flooring materials), the safe distance is doubled,

that is 400 mm;

−

the safe distance is to be doubled also when the fire reaction class is not proven.

Number of sections

-

5

6

7

Lenght L

mm

659

728

841

Fig.

№

. 9

Substructure dimensions

Fig.

№

. 10

Cast iron basement of the boiler

Tab.

№

. 7

Fire reaction class

Fire reaction class

Examples of building materials and products classified to the fire reaction class

(a choice from EN 13501-1+A1)

A1 – incombustible

granite, sandstone, concrete, bricks, ceramic tiles, mortars, fire plasters, ...

A2 – combustible with difficulty acumin, izumin, heraklith, lignos, boards and basalt felt, fibreglass boards, ...

B – hardly combustible

beech and oak wood, hobrex boards, plywood, werzalit, gypsum plasterboard , sirkolit,...

C (D) – medium combustible

pinewood, larch, whitewood, chipboard and cork boards, rubber flooring,...

E (F) – easily combustible

asphalt board, fibreboards, cellulose materials, polyurethane, polystyrene, polyethylene, PVC,…

Boiler positioning with regard to the necessary handling space:

−

basic environment AA5/AB5 according to

Č

SN 33 2000-1 ed. 2;

−

min. 1000 mm handling space must be left in front of the boiler;

−

minimum distance between the boiler rear side and wall is 400 mm;

−

at least from one side part, keep the access area to the rear boiler part

of 400 mm.

Placing of fuel:

−

dry fuel has to be used in order to ensure its proper burning in the

boiler. Fuel stored in cellar or at least sheltered is recommended by the

manufacturer;

−

it is prohibited to store the fuel behind the boiler or next to the boiler in

the distance shorter than 400 mm;

−

it is prohibited to store the fuel between two boilers in the boiler room;

−

the manufacturer recommends to keep the distance between the boiler

and the fuel min. 1000 mm or store the fuel in a different room than the

boiler is installed.

Fig.

№

. 11

Boilers positioning in boiler room