USER MANUAL

QUARTER DUTY ONBOARD AIR SYSTEM

PRESSURE SWITCH WITH RELAY INSTALLATION

Your Onboard Air System comes complete with a pressure switch with relay that will turn on the compressor at

90 PSI, and off at 120 PSI. The pressure switch has a 1/8” NPT inlet at the bottom that will fit in one of the top

ports of the tank using thread sealant. (For Relay installation, see Relay Wiring Schematic contained in Figure 2.)

Pressure Switch with Relay Installation Tips:

1. Never install your pressure switch in direct line from the inlet port coming from the compressor.

Tank pressure can be misread by the pressure switch. Mount the pressure switch on the tank where it

receives reading from deflected air.

2. Never use a pressure switch that is rated beyond your compressor’s rated maximum working pressure

(150 PSI).

3. Replace with P/N 90100 should the pressure switch need replacement.

Installation Tips:

- When cutting air line tubing, always cut as squarely as possible. Use a hose cutter or razor blade.

- When routing air line tubing, always remember to avoid sharp edges, heat sources and tight bends.

(Air line must be routed at least 12 inches from exhaust systems & other heat sources.)

IMPORTANT - Drilling through firewall:

Always be sure of what is on the other side of the firewall before drilling.

Take care not to damage your vehicle’s electronic systems or components.

Wiring an ON/OFF Switch:

Using a relay: Run a wire to a simple two position switch that can be mounted on your dash or to your ignition

switch. This switch will turn off power to the whole system by shutting off power to the pressure switch via the

relay. The wire should be fused between the battery and your on/off switch.

Test Your System:

Installation is now complete. Run the compressor to build pressure in the air tank. When air pressure reaches

the pressure switch cut out pressure, the compressor will shut off. Spray all air line connections with soap and

water solution to check for leaks. If leaks are detected, air line may not be cut squarely or pushed all the way

in. Fix connections as needed. Periodically check your system’s fitting in this manner should your compressor

turn on more often than normal without frequent air use.

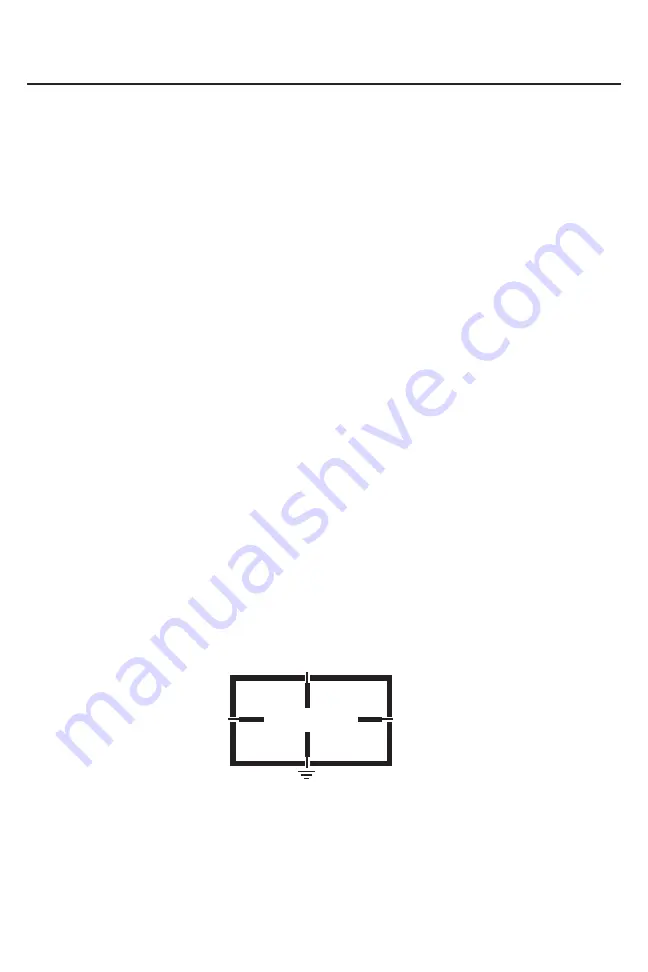

RELAY WIRING SCHEMATIC

Pressure Switch

86

Fused

12-Volt

30

To Ground

85

87

Compressor

(+) Lead

Relay Wiring Schematic:

(Figure 2)