MOUNTING AND WIRING

1. Disconnect ground cable from vehicle’s battery.

2. Temporarily position the air compressor in the location where it will be mounted.

3. Route ground wire to the negative post of the battery or to an appropriate grounding point

and cut ground wire to length as needed.

4. Mount air compressor with the four sets of bolts, nuts, washers, and locking washers provided.

(See Mounting Instructions) Use of thread locker is recommended.

5. This air compressor comes with a Heavy Duty Heat Resistant Stainless Steel Leader Hose.

The leader hose is designed to prolong the life of your air line. Follow the direction on the leader

hose packaging for installation.

6. Select proper location to mount leader hose with hose bracket provided. Avoid locations where

leader hose may become tangled with wires and other hoses.

7. To mount hose bracket, drill hole with 3/16” drill bit and push the self–anchoring hose bracket

pin into the drilled hole. Route leader hose through hose bracket and secure hose by pressing

bracket clamp into locked position.

8. To remove hose from the hose bracket, simply press down on the hose clamp release tab to

release bracket clamp.

9. Connect compressor’s positive lead wire to one of the leads of your pressure switch. The use of

a relay is recommended. Refer to the Recommended wiring diagram in (Fig. 4).

10. Make sure that your compressor setup is properly fused. For appropriate fuse size, refer to amp

draw of compressor in the specifications section of this manual.

11. Always locate fuse as close as possible to power source.

12. Before connecting to power source, re-check to make sure that all connections are made properly.

13. Connect and test compressor system by running the compressor for a short time to build up

pressure in your air tank.

14. Once air pressure reaches preset cut out pressure of your pressure switch, the compressor will

shut off. Inspect all air line connections for leaks with soap and water solution. If a leak is

detected, the air line may not be cut squarely or pushed all the way in. Fix leaking connections

as needed.

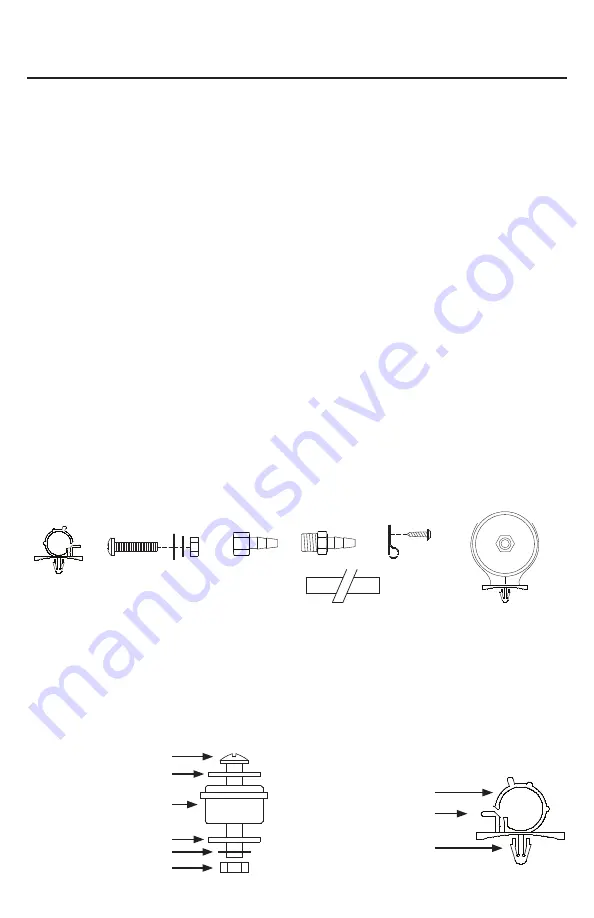

(Fig. 1) 150C-IG Compressor Installation Parts List:

A. Hose Bracket (1pc)

B. Mounting Bolts (4pcs)

C. Flat Washers (8pcs)

D. Locking Washer (4pcs)

E. Nuts (4pcs)

F. 1/8” NPT F x 1/4” Barbed Fitting (1pc)

G. 1/8” NPT M x 1/4” Barbed Fitting (1pc)

H. Air Line Clips (3pcs)

I. Screws (3pcs)

J. Remote Inlet Air Filter with Filter Element (1pc)

K. 1/4” Airline

(Fig. 2) Compressor

Mounting Hardware

B. Mounting Bolt

C. Flat Washer

D. Locking Washer

E. Nut

K. Vibration Isolator

USER MANUAL

150C-IG COMPRESSOR KIT

REDUCER

B

A

C D E

F

G

H

I

J

(Fig. 3) Leader Hose Bracket

A. Hose Clamp

M. Clamp Release Tab

N. Self-Anchoring Pin

B

C

C

D

E

K

REDUCER

A

M

N

K

Summary of Contents for 150C-IG

Page 1: ......